Interested in starting a mini oil mill? Our Mini Oil Mill Project Report PDF covers everything you need: setup costs, required machinery, production processes, and financial projections. Discover how to make your oil mill venture successful.

The mini oil mill business is revolutionizing the edible oil industry. These compact and efficient units are designed to produce high-quality oils from various seeds, catering to the diverse and very peculiar food habits of different regions. The edible oil industry is crucial, as it meets the fundamental needs of consumers and supports numerous related industries, including oil milling and the oil mill plant.

Setting up a mini oil mill offers numerous benefits, including lower initial investment, manageable operational costs, and the ability to produce a range of oils to meet local demand. This not only ensures a steady revenue stream but also provides an opportunity to contribute to the local economy and promote healthier dietary choices.

Oil Variety and Versatility: Mini oil mills are versatile and capable of processing a variety of oilseeds to produce popular edible oils like mustard oil, groundnut oil, sunflower oil, and coconut oil. These oils are staples in many kitchens, serving as essential cooking mediums for a wide range of dishes.

Mustard Oil Uses: Mustard oil is particularly popular in non-vegetarian food preparations due to its strong flavor and high smoking point.

Groundnut Oil Preferences: Groundnut oil, known for its neutral taste, is preferred for frying and baking.

Sunflower Oil Benefits: Sunflower oil, with its mild taste and nutritional benefits, is gaining popularity as a healthier alternative.

Coconut Oil Appeal: Coconut oil is celebrated for its unique flavor and health benefits, making it a favorite in many regional cuisines.

Advanced Machinery Utilization: Mini oil mills utilize various oil extraction machines, oil expellers, and oil press machines to efficiently process these oil seeds.

Quality Assurance: The use of advanced oil mill machinery and oil mill machine ensures that the oil extracted is of high quality and retains its nutritional value.

Attractive Investment: This capability to process multiple types of oils makes mini oil mills an attractive investment, especially with mini expeller power.

Seed Cleaning and Preparation: The manufacturing process in a mini oil mill begins with cleaning and preparing the seeds. This crucial step involves removing impurities, dust, and foreign materials from the raw materials to ensure the quality of the final product. Proper cleaning and preparation are essential to maximize oil yield and maintain product standards.

Oil Extraction: The next step is oil extraction, where the cleaned seeds are fed into an oil extraction machine or oil expeller. This machine uses mechanical pressure to extract oil from the seeds. In some cases, a filter press machine is used to further purify the oil, removing any remaining solid particles. This step may also include optional refining processes to enhance the oil’s flavor and appearance through multi seed oil extraction.

Packaging and Storage: Finally, the oil is packaged and stored using suitable press machines and packaging equipment. Proper packaging and storage are vital to maintaining the oil’s freshness and preventing contamination. Detailed packaging details ensure that the product reaches consumers in optimal condition, ready for use in their kitchens.

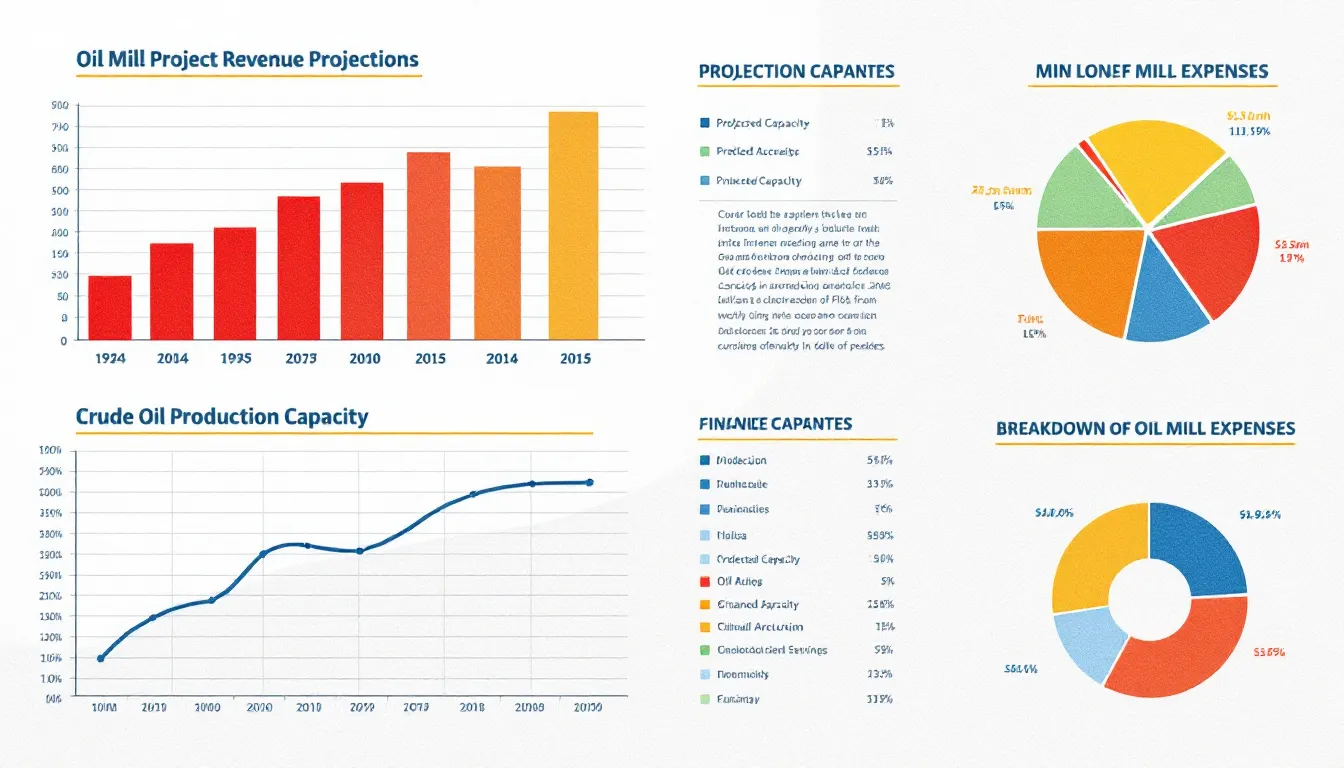

Financial Projections and Revenue Streams: Financial projections for a mini oil mill project are a crucial component of the project report. The revenue model typically includes income from oil sales and by-products like oil cake, which can be sold as cattle feed. A break-even analysis helps determine the minimum capacity utilization required to cover costs and achieve profitability.

Return on Investment (ROI) and Profit Margins: Expected ROI and profit margins are vital for assessing the project’s feasibility. With proper planning and efficient operations, a mini oil mill can achieve a healthy return on investment. Profit margin estimations often show significant potential for growth, especially as the mill increases its processing capacity over time.

Break-even Analysis: A break-even analysis is an essential tool that helps in understanding the minimum capacity utilization needed to cover costs. It provides insights into the financial health of the mini oil mill project and helps in strategic planning.

Growth Potential: Profit margin estimations often indicate significant growth potential. As the mini oil mill increases its processing capacity, the opportunity for higher profits also grows, making it a lucrative investment.

A mini oil mill project report serves as a roadmap for establishing the mill, detailing necessary steps and expected outcomes. It is essential for planning and guiding the project, helping to set clear objectives and benchmarks for the operation.

Having a detailed project report supports financial planning, resource management, and market analysis, which are crucial for the success of any mini oil mill. It provides a comprehensive overview of the project’s feasibility, ensuring that all aspects are considered before making significant investments.

A well-structured mini oil mill project report includes several key components. Firstly, it outlines the specific area required for operations, typically around 100 square meters. The report also details the total estimated investment, including costs for building, machinery, and working capital, which can reach around Rs. 6.38 lakhs.

Operational expenses such as raw material procurement, workforce salaries, and utility costs are meticulously planned to ensure sustainable profits. Working capital requirements for the first year are calculated based on projected capacity utilization, providing a clear financial roadmap for the business.

A sample mini oil mill project report PDF typically includes sections such as an introduction, market overview, and production process details. It outlines the types of oilseeds used and their respective oil content percentages, providing valuable insights into the raw materials and expected yields.

The report may also include a process flow diagram illustrating the steps in oil extraction and refinement, making it easier to understand the entire manufacturing process. This comprehensive guide helps potential investors and entrepreneurs visualize the project’s scope and operational requirements.

The estimated total cost for setting up a mini oil mill is around Rs. 6.38 lakhs, which can be financed through a combination of term loans and promoter’s own funds. A common ratio for debt equity is about 2.45:1, ensuring a balanced financial structure. Financial planning in the project report outlines necessary investments and operating costs, helping to avoid unnecessary financial risks.

Income from a mini oil mill is derived from both oil production and the sale of oil cake as cattle feed, providing multiple revenue streams. The first year of operation typically anticipates around 60% capacity utilization, leading to an estimated net profit of Rs. 1.20 lakhs. As capacity utilization increases to 75% in subsequent years, profitability improves significantly.

The break-even point is generally estimated at a capacity utilization level of 60%, meaning this is the minimum required to cover costs. Comprehensive project reports help in securing funding by providing potential investors with a clear understanding of costs and expected profits.

Point 1: Oil Expeller – An oil expeller is a crucial component in a mini oil mill. It is used to extract oil from various types of oil seeds through mechanical pressure, making it indispensable for efficient oil milling.

Point 2: Filter Press – A filter press is vital for purifying the extracted oil. It removes solid particles, ensuring that the oil is clean and ready for consumption or further processing.

Point 3: Steam Kettle and Boiler – These are essential for heating oil seeds to facilitate efficient oil extraction. The steam kettle and boiler work together to maintain the optimal temperature during the extraction process.

Point 4: Oil Press Machine – An integrated oil press machine enhances efficiency by filtering oil simultaneously during extraction. It is a versatile tool suitable for processing different oil seeds.

Point 5: Seed Cleaners and Cookers – Seed cleaners and cookers are important for preparing the raw materials. They ensure that the seeds are free from impurities and ready for the extraction process.

Point 6: Screw Elevator – The screw elevator is used to transport raw materials within the mill, ensuring smooth and continuous operations without manual intervention.

Point 7: Specialized Tools for Specific Seeds – Different tools are necessary for processing various oil seeds. For example, peanut shellers are used for peanut oil, while disc hullers are employed for cotton seed oil. These specialized tools optimize the extraction process for each type of

Quality assurance in mini oil mills starts with ensuring that the incoming raw materials are well-dried and free from mould growth. Dust, moisture, and pests can significantly affect the quality of oilseeds, making proper storage conditions crucial.

Storage of oil should be done in sealed containers to prevent rancidity and contamination from light and air. Implementing these measures ensures that the oil produced is of the highest quality and safe for consumption.

The edible oils market is projected to grow from USD 250.78 billion in 2024 to USD 306.92 billion by 2029, with a compound annual growth rate (CAGR) of 4.1%. Increasing disposable incomes and population growth in the Asia-Pacific region are driving the surge in the demand for high-quality edible oils.

Health-conscious consumer trends are increasing the demand for healthier oil varieties, influencing market dynamics. The global demand for sunflower oil is on the rise as consumers seek more affordable cooking oil alternatives. Government initiatives in various Asia-Pacific countries are enhancing domestic edible oil production, increasing market accessibility.

Market analysis within the report identifies potential customers and competitors, ensuring informed decision-making for the business. The success of mini oil mills indicates a potential shift back to local food systems, offering healthier alternatives to mass-produced cooking oils.

Quality specifications for the final oil product are commonly detailed in these project reports. Mini Oil Ghani Machines produce 100% pure and natural oil, ensuring that consumers receive a fresh and uncontaminated product.

Refining processes in mini oil mills may include neutralizing and deodorizing to remove impurities from the oil. These measures provide greater quality control, ensuring that the oil is fresh, pure, and contaminant-free.

Setting up a mini oil mill in India requires registration under the Companies Act or the Partnership Act, depending on the business structure chosen. Obtaining a food safety license from FSSAI is mandatory for operating a mini oil mill involved in the production of edible oils.

Businesses may need to secure a trade license or a GST registration to operate legally within their local jurisdiction. Compliance with environmental regulations is essential for mini oil mills to ensure waste management and pollution control.

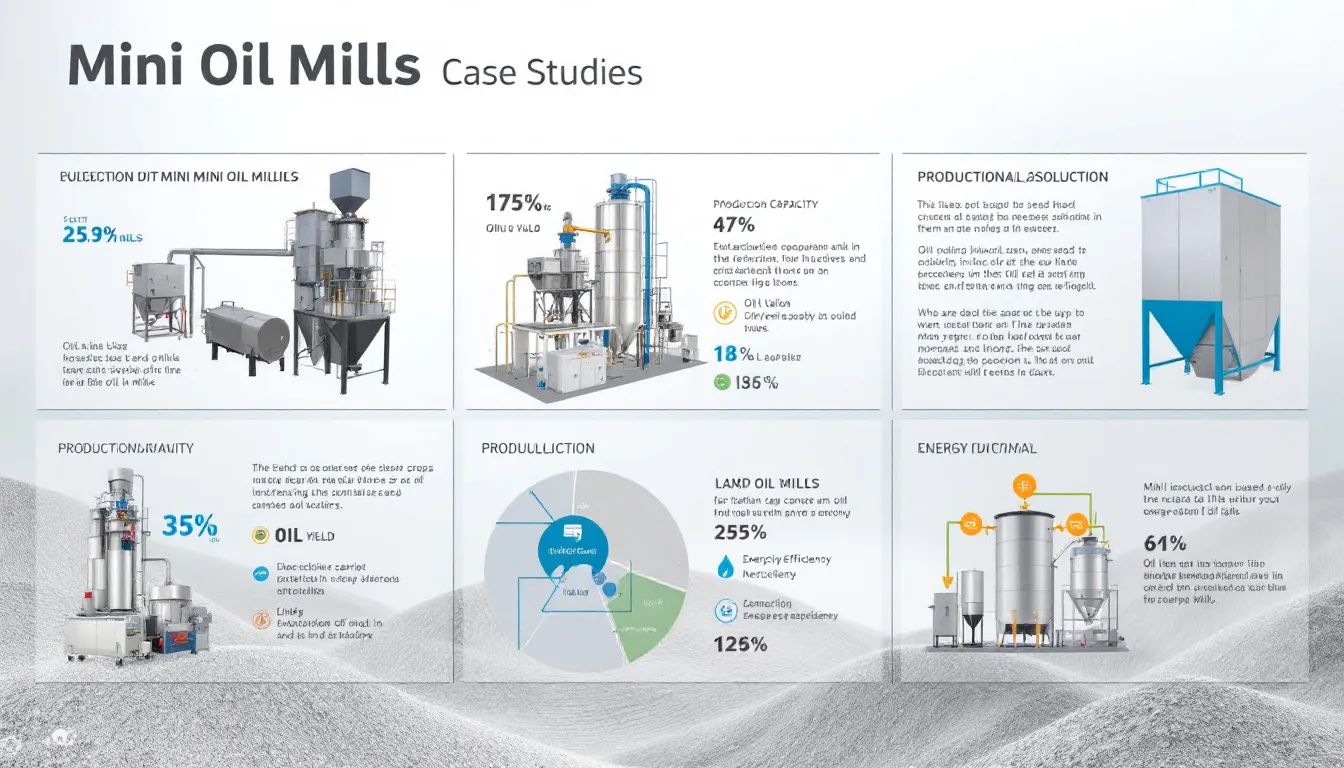

Sathiyam Marachekku Ennai started with a focus on coconut oil and later expanded to other oils and health foods, demonstrating versatility in product offerings. Vipi Marachekku Ennai adapted its business model to include homemade spice powders, addressing consumer demand for unadulterated products.

Both entrepreneurs from the case studies expressed a commitment to educating consumers about the benefits of cold-pressed oils through direct engagement. These case study mills engaged in custom hiring services for oilseed processing, fostering a direct relationship with consumers.

A key strength of mini oil mills is their ability to produce high-quality oil with minimal investment compared to larger installations. However, one significant weakness is limited production capacity, which may affect profitability in competitive markets.

There are substantial opportunities in the growing demand for organic and cold-pressed oils due to health consciousness among consumers. A potential threat to mini oil mills includes competition from large-scale oil producers who benefit from economies of scale.

Several government schemes support the establishment of mini oil mills. The PMEGP (Prime Minister’s Employment Generation Programme) provides subsidies for new ventures. NABARD & MSME Loan Schemes offer financial assistance specifically tailored for small and medium enterprises.

The Mudra Loan Scheme is another option, providing loans to micro and small enterprises to help them grow and thrive.

In summary, setting up a mini oil mill is a feasible and profitable business opportunity. The key takeaways include understanding the market potential, having a solid project report, and ensuring quality control measures.

Success factors involve efficient operations, strategic financial planning, and compliance with legal requirements. With the right approach, a mini oil mill can become a sustainable and lucrative venture.

If you’re planning to start a Mini Oil Mill Business, having a well-prepared project report is essential for securing loans, making informed decisions, and ensuring profitability. Our ready-made Mini Oil Mill Project Report provides complete details on investment, machinery, raw materials, manufacturing process, financial projections, and government subsidies.

Why struggle with research when you can get a professionally crafted project report instantly? Save time, avoid costly mistakes, and kickstart your oil mill business with confidence! 👉 Get your project report now and turn your business idea into reality! 🚀

Summing up, the mini oil mill business offers a promising opportunity for entrepreneurs looking to enter the edible oil market. With a comprehensive project report, you can navigate the complexities of starting and running a mini oil mill efficiently. Key points include understanding the manufacturing process, financial projections, market potential, and legal requirements.

This blog post has equipped you with the knowledge to make informed decisions and take the necessary steps towards establishing a successful mini oil mill. Embrace this opportunity, and let your entrepreneurial spirit drive you towards success in the edible oil industry.

A comprehensive mini oil mill project report should encompass area requirements, investment details, working capital, and operational expenses to ensure clarity and feasibility of the project. These components are essential for evaluating the project’s viability and operational effectiveness.

The estimated cost to set up a mini oil mill is approximately Rs. 6.38 lakhs. This investment covers the essential infrastructure and equipment needed for operation.

Mini oil mills can efficiently process a range of oils, such as mustard, groundnut, sunflower, coconut, soybean, sesame, and cottonseed oils. This versatility allows for various applications in food and industry.

A mini oil mill requires essential machinery such as an oil expeller, filter press, steam kettle, boiler, seed cleaners, and oil refining machines to operate efficiently. Investing in these components will ensure effective processing of oil.

Yes, government subsidies are available for setting up mini oil mills through schemes like PMEGP, NABARD, MSME Loan Schemes, and the Mudra Loan Scheme. These programs offer financial assistance to support your business venture.