Looking to set up a PVC pipe manufacturing plant? Our detailed PVC Pipe Manufacturing Plant Project Report covers everything you need to know. From market analysis and essential raw materials to machinery, financial projections, and regulatory requirements, we’ve got you covered. This guide will provide you with a comprehensive roadmap to successfully launch and operate your PVC pipe manufacturing business.

The PVC pipe industry in India is experiencing unprecedented growth, driven by significant infrastructure development and an expanding housing market. Over the last decade, the plastic pipe sector in India has seen an impressive 8% compound annual growth rate, reflecting the increasing demand for durable, cost-effective piping solutions. With the Indian plastic pipe market projected to reach Rs 500 billion by FY25, the opportunities for entrepreneurs in this sector are immense.

PVC pipes are vital in various critical sectors, including electrical applications, irrigation systems, and the construction industry. Their versatility and durability make them a preferred choice over traditional materials, especially in a country where infrastructure is rapidly evolving. Despite the significant usage, the adoption of plastic pipes in India remains below the global average, indicating vast untapped potential for market growth.

This market potential is further highlighted by the increasing adoption of PVC pipes in residential, commercial, and industrial applications. As India continues to urbanize and develop its infrastructure, the demand for reliable and efficient piping solutions will only grow, making now the perfect time to invest in the PVC pipe industry.

Comprehensive Market Research: Conducting thorough market research is essential to understand the dynamics of the PVC pipe industry. It helps identify key demand areas and potential growth opportunities within the market.

Applications of PVC Pipes: PVC pipes are widely used in water supply systems, spray irrigation, deep tube well schemes, and land drainage. Over 60% of the demand is for pipes with an outer diameter of up to 110 mm, which guides manufacturers in focusing on high-demand products.

Building Customer Relationships: Establishing strong relationships with customers is crucial for maintaining market share in the competitive PVC pipe industry. Loyal customers are more likely to make repeat purchases and provide valuable referrals, boosting sales.

Leveraging Data Analytics: Utilizing data analytics to measure marketing initiatives’ effectiveness is key. This helps optimize strategies, improve return on investment, and ensure marketing efforts are both efficient and effective.

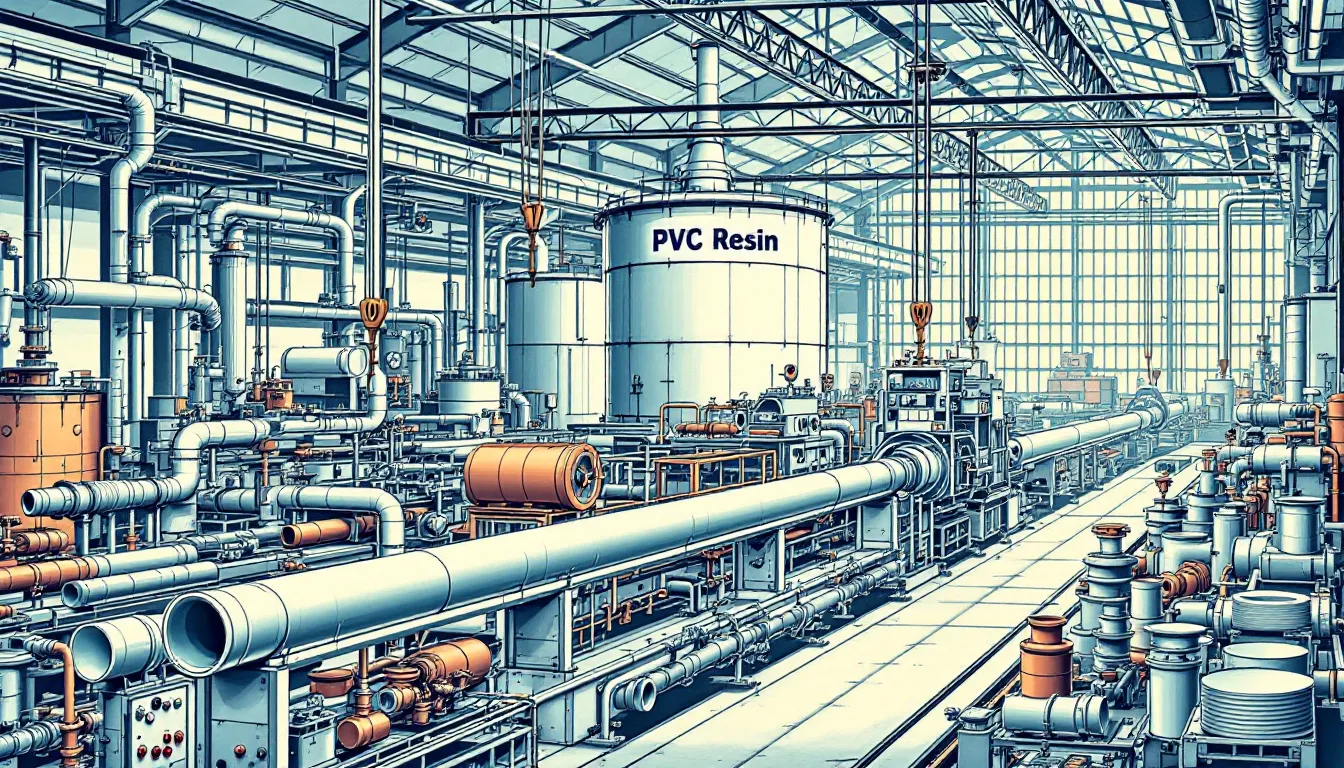

1. PVC Resin: The foundation of any successful PVC pipe manufacturing business lies in sourcing high-quality raw materials. PVC resin serves as the base material, providing the essential properties needed for durable and flexible pipes.

2. Stabilizers: Stabilizers, such as lead, barium, cadmium, tin, and stearate, are added to enhance the thermal stability and durability of the PVC, ensuring that the pipes can withstand various environmental conditions.

3. Lubricants: Lubricants like Buty-Stearate, Glycerol Moni-Stearate, and stearic acid are crucial for ensuring smooth processing during the manufacturing process. They reduce friction and wear on machinery, promoting efficient production.

4. Plasticizers: Plasticizers such as DOP, DIOP, DBP, and DOA are incorporated to improve the flexibility and quality of the final product, making the pipes more adaptable to different applications.

5. Fillers: Fillers like calcined clay are used to enhance the mechanical properties of the PVC pipes, providing additional strength and stability.

6. Sourcing Raw Materials: Understanding and sourcing these raw materials effectively is key to producing high-quality PVC pipes that meet industry standards. Proper procurement strategies ensure consistency and reliability in the manufacturing process.

Setting up a PVC pipe manufacturing plant involves several critical steps, starting with selecting the right location. Factors such as access to raw materials, transportation infrastructure, and regulatory compliance play a significant role in this decision. The chosen site should prioritize accessibility, availability of utilities, and adherence to environmental regulations to ensure smooth operations.

Designing an efficient plant layout is essential for optimizing workflow and resource utilization. The layout should accommodate essential machinery, including extruders, cutters, and cooling systems, to facilitate a seamless production process. Proper installation and alignment of machinery are crucial for maintaining production efficiency and preventing operational disruptions. Hiring skilled operators and providing comprehensive training on machinery operation and safety ensure the plant runs smoothly.

A thorough financial analysis is indispensable for assessing the profit margins, return on investment (ROI), and net present value (NPV) of the plant. This analysis should cover both capital and operational expenditures, including costs related to utilities, transportation, and human resources. Regular maintenance of production equipment is also necessary to prevent breakdowns and ensure longevity.

Factory License: Navigating the legal landscape is a crucial step in establishing a PVC pipe manufacturing business. Legally operating in India requires obtaining a Factory License, which ensures the manufacturing plant complies with local laws and safety regulations.

Trade License: A Trade License is mandatory for all manufacturing businesses, including PVC pipe manufacturers, to operate legally. This license allows the business to function within the legal framework and ensures adherence to regional business laws.

BIS Certification: Ensuring that the PVC pipes meet specific safety and quality standards requires BIS certification. This certification is crucial for gaining consumer trust and complying with Indian regulations.

ISO Certification: ISO certification further indicates that the manufacturing firm adheres to international quality management standards, enhancing its credibility and ensuring global competitiveness.

Trademark Registration: Trademark registration protects the brand identity of the business, preventing unauthorized use of the brand and ensuring that the business maintains its unique market presence.

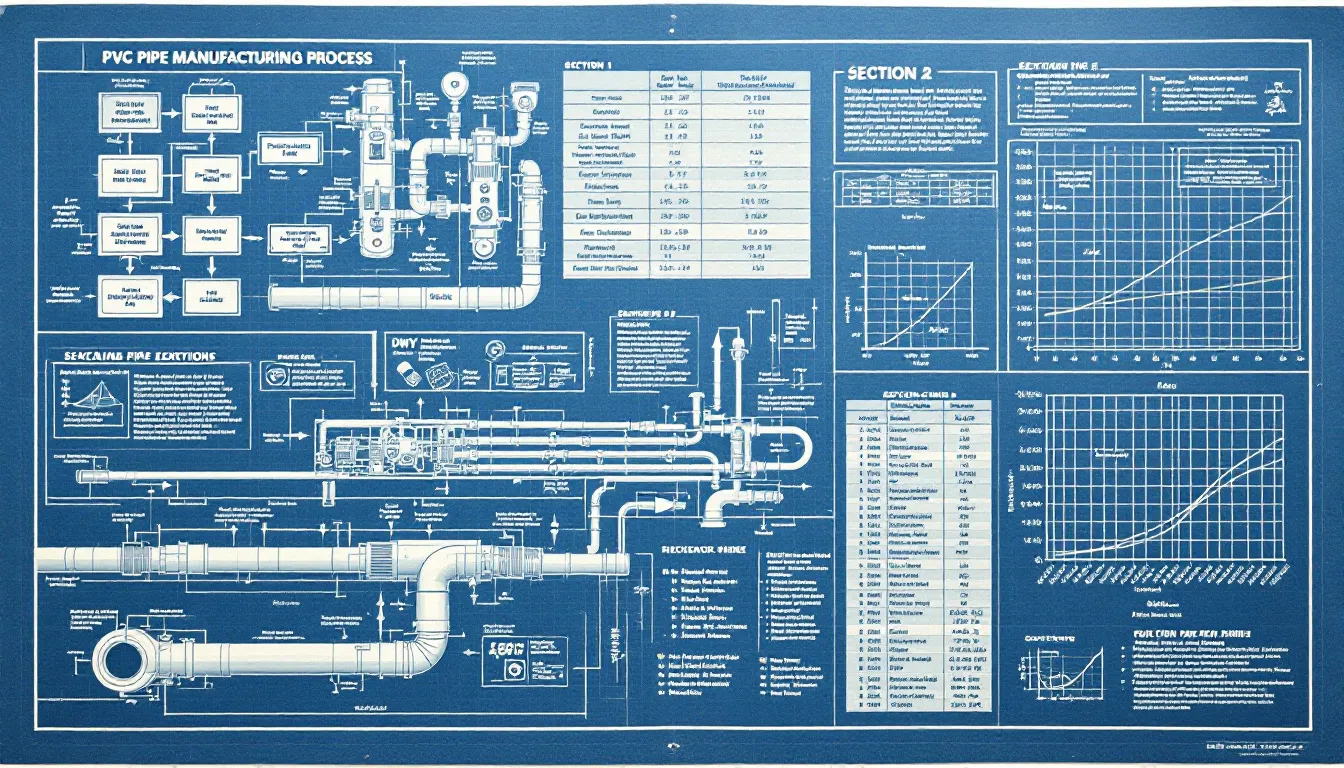

The manufacturing process of PVC pipes involves several stages, each crucial for producing high-quality pipes. This process begins with compounding and mixing, followed by the extrusion process, sizing and cooling, and finally, haul-off and cutting.

Each stage requires specific machinery and precise operations to ensure the final product meets industry standards.

Compounding and mixing are the initial stages of the PVC pipe manufacturing process. This stage involves preparing the PVC resin by blending it with specific additives such as stabilizers and lubricants. These additives enhance the flexibility, durability, and stability of the final product.

The thorough mixing of these components is essential to achieve the desired properties of the PVC pipes, making this stage vital for production success.

The extrusion process is a critical stage in PVC pipe manufacturing. During this stage, the compounded PVC is fed into a twin-screw extruder, which ensures thorough mixing and a consistent material flow. The melted PVC is then forced through a die to create the desired pipe shape.

This process is essential for forming pipes of specified dimensions and ensuring the quality of the final product.

After extrusion, the PVC pipes undergo sizing and cooling to maintain their shape and dimensions. A cooling tank, typically filled with water, is used to solidify the pipes. These tanks help set the shape of the extruded pipes, ensuring they meet the required specifications.

Pressure and vacuum sizing methods ensure consistent dimensions.

The haul-off and cutting stages are the final steps in the PVC pipe manufacturing process. The haul-off mechanism pulls the extruded pipes through the cooling section, ensuring they maintain a consistent length. This process is crucial for efficient production, as it continuously moves the pipes from the extruder to the cutting station.

After the haul-off process, the pipes are cut to the desired length using either manual or automated cutting systems.

Comprehensive Quality Control: Implementing a comprehensive quality control process is essential to ensure that the produced PVC pipes meet industry standards. BIS certification is crucial for maintaining quality control in PVC pipe manufacturing, as it ensures compliance with specific safety and quality standards.

Testing Equipment: Various testing equipment, including tools for impact resistance, hydrostatic pressure, and environmental stress cracking, are used to evaluate the pipes’ durability and performance.

Impact Resistance Assessment: Specific testing methods, such as Drop Weight Impact Testers, assess a pipe’s resistance to impact forces, simulating real-world handling conditions.

Hydrostatic Pressure Testing: This method evaluates the pipe’s ability to withstand internal pressure and its burst strength over time, ensuring reliability.

Environmental Stress Crack Resistance (ESCR): ESCR tests the durability of the pipes against cracking due to environmental stresses, ensuring long-lasting performance.

Importance of Testing: These testing methods are essential for maintaining the quality and compliance of PVC pipes with industry standards, ensuring that the pipes are safe and effective for their intended applications.

Proper Storage Practices: To maintain the quality of PVC pipes, they should be stored on a flat surface with supports every 1.5 meters to prevent bending. This ensures that the pipes retain their structural integrity.

Avoid Overstacking: It’s important to keep the sockets of the pipes free and avoid stacking them over 1.5 meters high to prevent damage. This practice helps in maintaining the pipes’ shape and usability.

Sunlight Protection: Covering pipes exposed to sunlight with opaque materials that allow ventilation prevents overheating. This protection is essential to avoid any thermal damage to the pipes.

Careful Transportation: Transportation of PVC pipes requires careful handling to avoid damage. When loading pipes for transport, it’s best to load larger diameters first to ensure stability and prevent damage to smaller pipes.

Maintaining Integrity: These practices help maintain the integrity of the pipes during pipe storage and distribution, ensuring they reach the end-users in perfect condition.

A comprehensive investment and cost analysis is critical for assessing the financial viability of a PVC pipe manufacturing plant. The PVC pipe market in India is projected to grow from $5.25 billion in 2024 to $7.43 billion by 2030, with an annual growth rate of 5.79%. Government initiatives aimed at improving water supply and sanitation, especially in rural areas, significantly increase the demand for PVC pipes. This growing demand presents a lucrative opportunity for investors.

The capital investments required for a PVC pipe manufacturing plant include machinery, raw materials, and operational expenses. Operating expenses cover costs related to utilities, transportation, and human resources necessary for efficient plant functioning.

A thorough financial analysis helps assess profit margins, return on investment (ROI), and net present value (NPV), ensuring the project’s financial success.

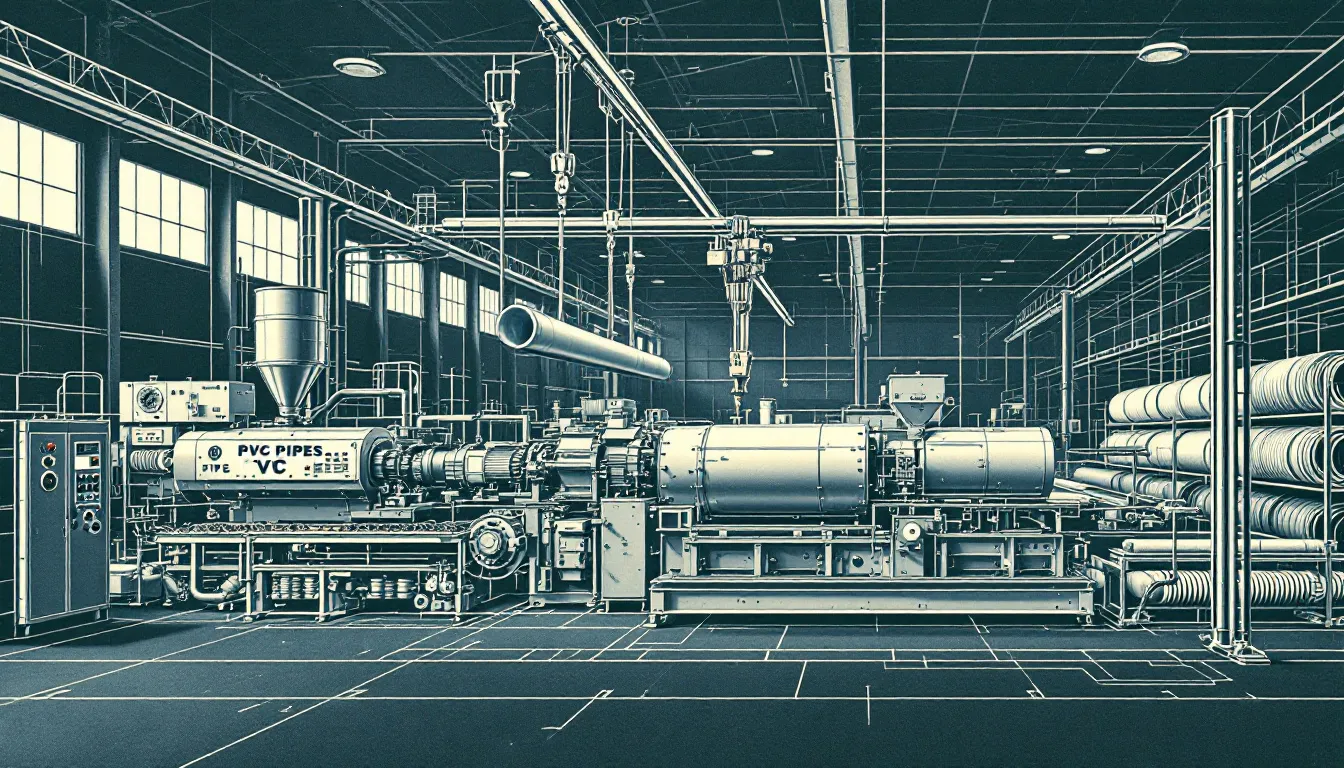

Extrusion Machines: These are the heart of the PVC pipe manufacturing process. Extrusion machines, particularly twin-screw extruders, are responsible for melting and shaping the PVC resin into pipes. They ensure consistent flow and uniformity in the pipe’s dimensions.

Cooling Tanks: Essential for solidifying the pipes after extrusion, cooling tanks use water to cool down and set the pipe’s shape. This step is crucial for maintaining the pipes’ structural integrity and meeting specified dimensions.

Cutters: Once the pipes are formed and cooled, cutters are used to slice them into desired lengths. This equipment can be either manual or automated, ensuring precision and efficiency in production.

Haul-Off Units: These units pull the extruded pipes through the cooling section, maintaining a steady pace and consistent pipe length. They are vital for ensuring smooth and continuous production flow.

Regular Maintenance: Regular upkeep of all machinery is crucial to prevent breakdowns and ensure longevity. This includes routine checks and servicing to keep the machines running efficiently and avoid costly downtime.

Supplier Reliability: Sourcing machinery from reputable suppliers ensures quality and reliability. It’s important to understand the specifications of each machine to match production needs and maintain efficient operations.

Installation and Alignment: Proper installation and alignment of machinery are critical for smooth production operations. Ensuring that all equipment meets technical requirements and is correctly aligned helps prevent operational disruptions.

Our comprehensive project report for a PVC pipe manufacturing plant provides a detailed roadmap to success. It includes market overviews, raw material requirements, and utility needs, providing a complete picture of what it takes to set up a successful plant.

The report also covers financial aspects such as capital investments, operating expenses, and income projections, helping you assess the project’s viability.

To ensure compliance with legal and regulatory requirements, a PVC pipe manufacturing business must obtain several licenses and approvals. This includes a Trade License, which is essential for operating within local laws, and BIS certification, which guarantees that the pipes meet specific safety and quality standards set by Indian regulations.

Additionally, ISO certification demonstrates adherence to international quality management standards, enhancing the business’s credibility. Full control over the environmental impact of the manufacturing process is also critical for long-term sustainability.

Conducting a SWOT analysis provides valuable insights into the strengths, weaknesses, opportunities, and threats associated with the PVC pipe manufacturing business. Strengths might include the high demand for PVC pipes and the business’s ability to meet industry standards. Weaknesses could involve the initial capital investment and potential operational challenges.

Opportunities abound in the growing infrastructure sector and increasing demand for irrigation facilities. However, threats such as market fluctuations and regulatory changes must be carefully managed to ensure long-term success.

Identifying and mitigating risks is crucial for the stability of a PVC pipe manufacturing business. Market risks include fluctuating raw material prices and changing consumer preferences. Operational risks involve machinery breakdowns and workforce management challenges. Financial risks pertain to the volatility in operating expenses and potential funding shortfalls.

Developing a comprehensive mitigation plan, such as securing reliable suppliers, regular equipment maintenance, and diversifying funding sources, can help address these risks effectively.

Effective marketing strategies are essential for capturing market share in the competitive PVC pipe industry. Emphasizing the unique qualities of PVC pipes, such as their lightweight, cost-effectiveness, and ability to withstand high pressures, can attract customers in the agricultural sector, particularly for deep tube well schemes and irrigation systems. The growing emphasis on sustainable agricultural practices also drives the demand for PVC pipes in irrigation.

Leveraging digital advertising through social media and email campaigns can reach targeted customers cost-effectively, highlighting the benefits of PVC pipes in various applications. Diversifying the product range to include different types of PVC products can cater to various market needs, boosting sales and profit margins.

Investing in targeted marketing campaigns that emphasize the unique qualities of PVC products can justify premium pricing and attract discerning customers.

Environmental sustainability is a crucial aspect of the PVC pipe manufacturing process. The production of PVC pipes is relatively clean, primarily using salt and ethylene, which minimizes the use of harsh chemicals. Polyvinyl chloride pipes have a long lifespan of up to 70 years, reducing the need for frequent replacements and thereby minimizing waste.

Additionally, PVC pipes are highly recyclable, with options for mechanical recycling that help reduce greenhouse gas emissions. Adhering to these environmental guidelines ensures the business operates sustainably and responsibly.

Embarking on a PVC pipe manufacturing venture offers substantial opportunities, given the industry’s robust growth and diverse applications. This comprehensive guide has covered essential aspects, from understanding market dynamics and sourcing raw materials to setting up the manufacturing process and ensuring quality control. By adhering to regulatory requirements, implementing effective marketing strategies, and maintaining environmental sustainability, you can set the foundation for a successful PVC pipe manufacturing business. The future is promising, and with the right approach, your venture can thrive in this burgeoning industry.

PVC pipes are mainly utilized in water supply systems, irrigation, and drainage applications due to their durability and resistance to corrosion. Their versatility makes them a preferred choice for various plumbing and agricultural needs.

To start a PVC pipe manufacturing business in India, you must obtain a Factory License, Trade License, BIS certification, and ISO certification to comply with regulatory standards. This is essential for ensuring quality and legality in your operations.

The essential raw materials for PVC pipe manufacturing are PVC resin, stabilizers, lubricants, and fillers. These components are crucial for ensuring the quality and durability of the pipes.

To ensure the quality of PVC pipes, it is essential to implement comprehensive quality control processes and utilize testing equipment like Drop Weight Impact Testers and Hydrostatic Pressure Testing. This approach guarantees that the pipes meet industry standards and perform effectively.

PVC pipes offer significant advantages over traditional materials by being lightweight, cost-effective, and durable, while also boasting a long lifespan and lower CO2 emissions. This makes them an environmentally friendly choice that is both efficient and sustainable.