Looking to start a notebook manufacturing plant? This notebook manufacturing plant project report provides a comprehensive overview of everything you need to know: market analysis, setup costs, essential machinery, and profitability. Get the insights to make informed decisions.

The notebook manufacturing business is a cornerstone of the education and office supplies industry. Notebooks are indispensable for students throughout their entire schooling and higher education, as well as for professionals in various fields. The demand for quality exercise notebooks and white paper exercise notebooks is steadily increasing, driven by the ever-growing need for written documentation and creative expression in both educational and professional settings. The notebook business is thriving as a result.

Given the robust market potential, investing in a notebook manufacturing plant presents a lucrative opportunity for a notebook manufacturing company. The industry is expected to grow, fueled by the rising number of educational institutions and the consistent demand for reliable stationery products.

This growth is not confined to traditional markets but is also expanding in emerging markets where literacy rates and urbanization are on the rise.

Global Market Growth: The global notebook manufacturing industry is poised for significant growth, with the global notebook market projected to expand from USD 165.87 billion in 2025 to USD 238.46 billion by 2032, reflecting a compound annual growth rate (CAGR) of 5.32%. This surge is driven by increasing remote work and online education, which have underscored the importance of notebooks as essential tools for productivity.

Indian Market Dynamics: In India, the notebook industry is experiencing steady growth due to various factors including government initiatives to boost education and rising aspirations for higher education. The market is also witnessing a shift in consumer preferences from affordable local brands to higher-quality products, highlighting the evolving landscape of the notebook market.

Challenges from Digitization: However, digitization poses challenges, encouraging paperless transactions and impacting traditional notebook sales. Despite these challenges, the demand for notebooks in educational contexts remains strong, particularly among students, offices, wholesale buyers, and retailers.

E-commerce Influence: The rise of e-commerce platforms has further enhanced consumer access to stationery products, contributing to increased sales. Additionally, the trend towards eco-friendly materials and sustainable practices is influencing the industry, with more consumers seeking environmentally responsible options.

The backbone of any notebook manufacturing business lies in its raw materials. Essential raw materials include paper, cover materials, and binding components. The paper used can range from standard white paper to recycled paper, which contributes to environmental sustainability and can be sourced from local paper mills or scrap dealers. This not only helps in reducing costs but also appeals to the growing segment of eco-conscious consumers.

The outer cover of notebooks can be made from a variety of materials, including plastic, leather, fabric, and cardboard, offering flexibility in design and functionality. Purchasing raw materials in bulk can result in significant cost savings, making it a strategic move for new and established notebook manufacturing companies alike.

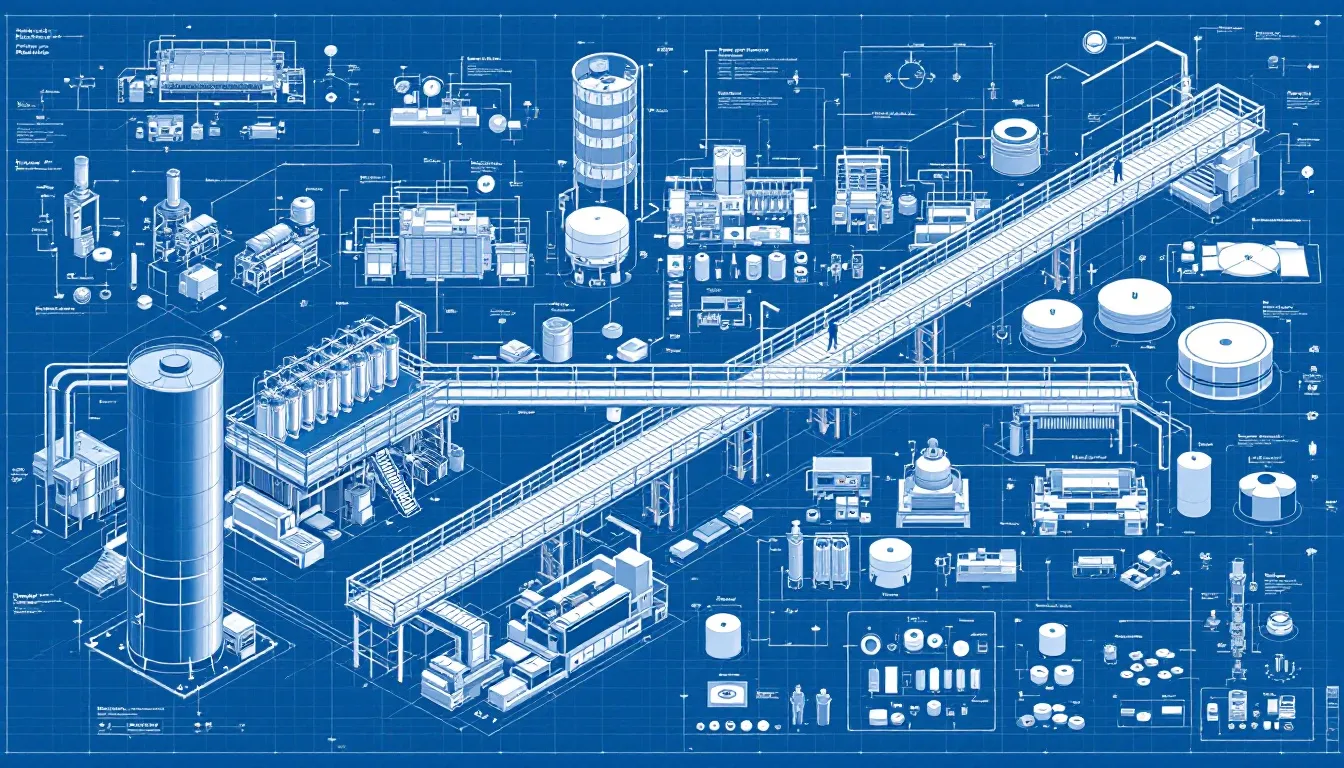

Investing in the right combination of these machines is a key success factor for any notebook manufacturing business, ensuring efficient and high-quality production.

1. Ruling the Paper: The notebook manufacturing process starts with ruling the paper. This involves printing lines or grids on the paper, which serves as a guide for writing.

2. Folding the Paper: Once ruled, the paper is folded into the desired size. This step is crucial for creating the pages of the notebook.

3. Arranging the Pages: The folded pages are then arranged in a specific order to ensure a coherent and functional notebook.

4. Perforating the Pages: Perforation is done to allow easy tearing of pages if needed. This step is essential for certain types of notebooks.

5. Binding the Notebook: Binding involves securing the arranged pages together using various methods like stitching or gluing, ensuring durability.

6. Cutting the Notebooks: The bound notebooks are then cut to the final desired size, ensuring uniformity and precision.

7. Packaging for Distribution: Finally, the notebooks are packed into boxes for distribution, ensuring they are ready for sale and transportation.

Using automatic or semi-automatic machines can significantly enhance production efficiency. An automatic notebook making machine can produce between 6000 to 8000 notebooks daily, while a semi-automatic one has a capacity of 5000 to 6000 notebooks per eight-hour shift. Specialized machinery ensures that each notebook is produced quickly and efficiently.

Establishing a notebook manufacturing plant involves significant infrastructure and setup costs. These costs include:

The selection and procurement of machinery also constitute a major portion of the capital investment. Proper planning of the plant layout is essential to ensure efficient operations and reduce potential operational costs.

Investing in a well-thought-out infrastructure can lead to long-term savings and enhance the overall efficiency of the manufacturing process. This includes not only the physical setup but also the integration of utility requirements such as electricity and water supply, which are critical for smooth operations and managing infrastructure costs.

Choosing the right location for a notebook manufacturing plant is crucial for its success. Ideal locations include urban, semi-urban, and industrial areas that offer the necessary infrastructure and accessibility. Space requirements must accommodate machinery, storage, and office areas to ensure smooth workflow and efficient use of space.

Utility requirements such as electricity and water supply are fundamental to the plant’s operations. Additionally, proximity to raw material suppliers and transportation hubs can reduce logistics costs and enhance the overall efficiency of the manufacturing process.

Human resources are a critical component of any manufacturing business. The costs associated with hiring and maintaining a skilled workforce must be factored into the overall investment. Implementing performance management systems can help improve employee productivity by setting clear expectations and providing regular feedback.

Investing in learning and development initiatives is essential for upskilling employees, enabling them to adapt to new technologies and manufacturing processes. This not only enhances the capability to manage risks effectively but also ensures operational continuity through succession planning.

Creating a risk-aware culture encourages proactive engagement from employees in identifying and managing potential threats.

A comprehensive financial analysis is vital for understanding the economic viability of a notebook manufacturing business. This involves detailed assessments of capital investments, project funding, operating expenses, and income and expenditure projections. On average, the annual profit for a notebook manufacturing business is approximately 15 lakhs, making it a profitable venture.

To maintain profitability, it’s crucial to:

A thorough financial analysis report can also boost investor confidence by detailing revenue, expenses, and projected profits.

1. Break-even Analysis: Conducting a break-even analysis is essential to ascertain the sales volume at which total revenues equal total costs. This provides a clear understanding of the business’s financial health.

2. Regular Financial Assessments: Implement regular financial assessments to identify operational inefficiencies and areas where operating costs can be reduced, thus improving overall profitability.

3. Predictive Financial Modeling: Utilize predictive financial modeling to forecast future business performance based on historical data, aiding in informed decision-making and investment attraction.

4. Contingency Planning: Establish contingency plans to enhance resilience against unexpected operational disruptions, ensuring business continuity.

5. Diversification of Suppliers: Diversify suppliers to mitigate supply chain risks, ensuring a consistent supply of raw materials and reducing dependency on single sources.

6. BIS Certification: Obtain BIS certification to minimize the risk of product recalls and associated penalties, ensuring compliance with industry standards.

A well-rounded marketing and distribution strategy is essential for the success of a notebook manufacturing business. Here are key points to consider:

Creative Covers: Designing creative covers that include promotional content can make notebooks more appealing to consumers and local businesses.

Digital Marketing: Effective digital marketing, including social media outreach, can significantly influence purchasing decisions and broaden market reach.

Distribution Channels: Utilizing both direct and indirect distribution channels can enhance sales and collaboration.

Customer Preferences: Understanding customer preferences is crucial when choosing distribution channels for notebooks.

Data Analytics: Data analytics can guide decisions on the most effective distribution channels, ensuring that the marketing strategy is tailored to the target audience.

BIS CRS Registration: Obtaining BIS CRS registration enhances brand credibility and consumer trust, which can further boost sales.

Operating a notebook manufacturing business in India requires obtaining several certifications and registrations. BIS CRS registration is mandatory for confirming compliance with safety and quality standards. The certification process involves submitting various documents and undergoing testing to meet technical and performance criteria.

The registration process for BIS CRS typically takes 20-25 days after submitting the required documentation. Obtaining these certifications is vital for legally operating a notebook manufacturing business and accessing government contracts and tenders.

Proper packaging and transportation are critical to ensuring that notebooks reach their destination in perfect condition. Selecting appropriate packaging materials is crucial to protect notebooks during shipping. Using sturdy boxes and incorporating additional padding inside the box can help prevent damage during transport.

Labeling packages clearly with sender and receiver information minimizes the risk of misdelivery. Ensuring that transportation methods are reliable and efficient is essential for maintaining product quality and customer satisfaction.

The notebook manufacturing industry presents several promising investment opportunities, driven by emerging trends and evolving consumer preferences. Customization and personalization of notebooks are becoming significant trends, as consumers prefer unique designs and personal touches in their stationery. The integration of digital technologies like e-ink displays and cloud synchronization is enhancing user experience and market appeal.

These trends open up substantial investment opportunities for developing customized, tech-integrated notebook designs. As the industry continues to evolve, staying ahead of these trends can provide a competitive edge and drive long-term growth.

Strengths: High Demand – The notebook manufacturing business enjoys robust demand, fueled by educational institutions and office requirements, ensuring a steady market for products.

Weaknesses: Raw Material Dependency – The reliance on raw materials like paper can pose challenges, especially if supply chains are disrupted, affecting production continuity.

Opportunities: Export Markets – There is significant potential for growth by tapping into export markets, allowing notebook manufacturers to expand their reach and increase revenue.

Threats: Market Competition – Intense competition from established brands and the rise of digital alternatives can threaten traditional notebook sales and market share.

Understanding these aspects is essential for strategic planning and achieving long-term success in the notebook manufacturing industry.

In summary, the notebook manufacturing industry offers a wealth of opportunities for growth and profitability. From understanding the essential raw materials and machinery requirements to navigating financial considerations and market strategies, this comprehensive guide has covered all aspects of setting up a successful notebook manufacturing business.

As the demand for quality stationery continues to rise, staying informed about industry trends and best practices will be key to maintaining a competitive edge. With the right approach, investing in a notebook manufacturing plant can lead to significant returns and long-term success.

The essential raw materials for notebook manufacturing are paper, cover materials such as plastic or fabric, and binding components. Utilizing recycled paper can enhance sustainability in the production process.

Setting up a notebook manufacturing plant typically involves significant costs related to land acquisition, construction, utility supply, and machinery procurement. Careful planning of the plant layout is essential for minimizing operational expenses.

To operate a notebook manufacturing business in India, obtaining BIS CRS registration is essential to ensure compliance with safety and quality standards. This registration process generally takes about 20-25 days following the submission of necessary documentation.

Key machinery requirements for notebook manufacturing include essential equipment such as paper cutters, binding machines, staplers, punching machines, and gluing machines, with cutting and binding machines being particularly critical to the production process.

The notebook manufacturing industry is increasingly focusing on customization and personalization, integrating digital technologies such as e-ink displays, and prioritizing eco-friendly materials. These trends reflect a shift towards more personalized and sustainable products for consumers.