Thinking of starting a ceramic tile manufacturing business? Our project report on ceramic tiles covers everything from cost breakdowns to industry trends and operational steps, helping you create a detailed business plan for your venture. Dive in to get the essential information you need for a successful venture.

Ceramic tiles are a popular choice for flooring and wall coverings due to their durability, aesthetic appeal, and ease of maintenance. Manufacturing ceramic tiles in India is particularly profitable, thanks to the growth in the construction and infrastructure sectors.

Urbanization and higher consumer spending on home aesthetics have driven up the demand for ceramic tiles, creating a lucrative business opportunity.

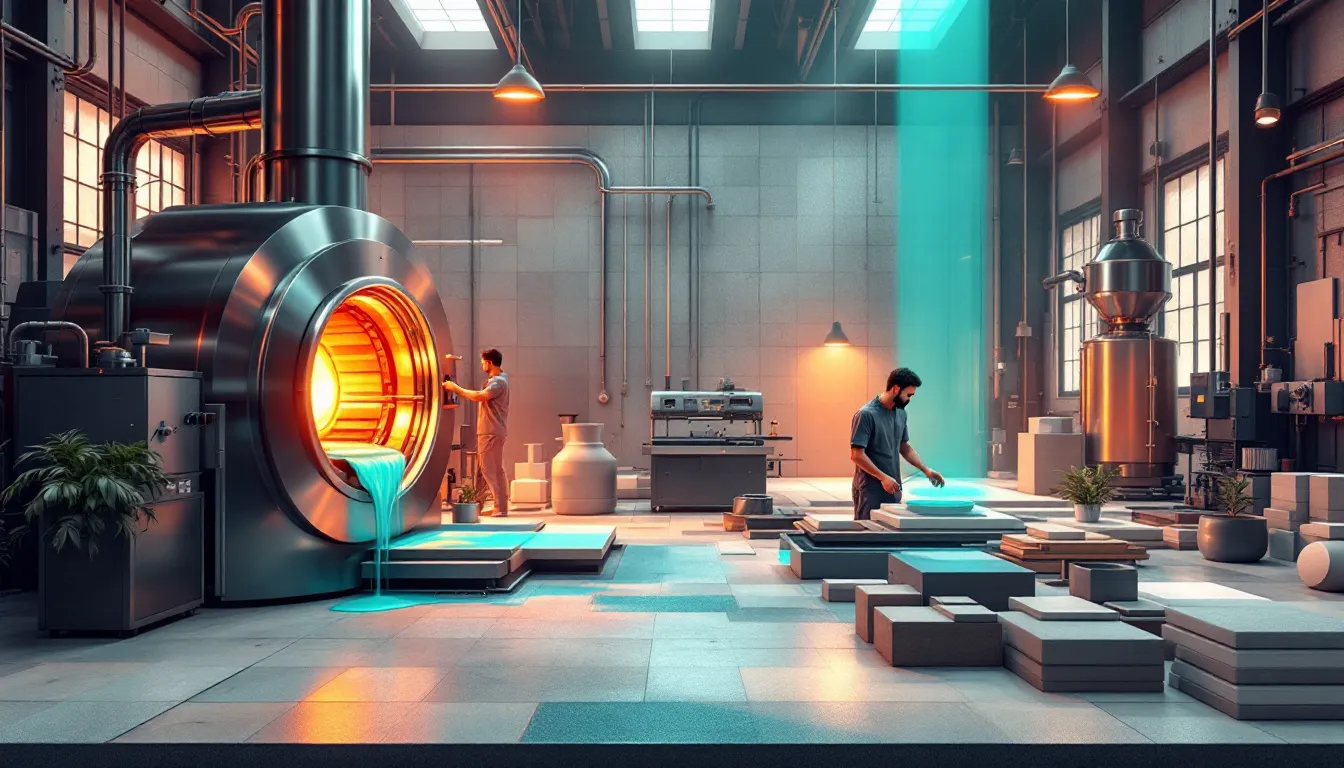

This section provides a detailed process flow of the manufacturing process for ceramic tiles, offering an extensive overview of each step involved.

Each stage of the production process is meticulously monitored to maintain high-quality standards, ensuring that the final ceramic tiles are reliable and meet customer expectations.

The primary raw materials required for ceramic tile manufacturing include:

The initial phase of tile production involves:

Investing in a ceramic tile manufacturing business requires understanding the costs involved. Our project report offers a detailed analysis of capital investments, including machinery costs and working capital requirements, along with profit margin estimates to gauge potential returns.

By breaking down costs and providing comprehensive financial analysis, this report helps you plan investments more effectively and ensure financial viability.

Setting up a ceramic tile manufacturing plant involves capital expenditures for machinery and infrastructure.

Our project report details these project costs, helping you understand the financial outlay required to establish and operate your manufacturing facility.

Initial investments for a ceramic tile factory include machinery costs, land acquisition, and site development. Machinery investments alone can exceed ₹25 million, depending on technology and capacity, covering kilns, presses, molds, and other essential equipment.

Capital costs also cover infrastructure development and facility setup, ensuring efficient production.

Running a tile manufacturing plant involves ongoing expenses like labor, utility costs, and routine equipment maintenance. Monthly operational expenses include raw materials, employee wages, and utility bills. Efficient management of these expenses is crucial for profitability and operational efficiency.

Unexpected increases in raw material prices can impact profit margins, making it essential to have a robust financial plan to manage these costs raw material requirements and ensure smooth operations.

Financial projections are crucial for assessing the potential success and sustainability of a ceramic tile manufacturing business. Industry profit projections indicate robust growth driven by increasing demand and market expansion. Analyzing the cash flow statement helps anticipate cash inflows from sales and outflows for operational costs, ensuring liquidity.

A detailed balance sheet analysis highlights the financial position of your manufacturing plant, providing an overview of assets, liabilities, and shareholders’ equity. These financial forecasts help plan for the future and make informed decisions to sustain and grow your business.

The market potential for ceramic tiles is immense, driven by government initiatives focused on the housing sector and sanitation, and increasing disposable income of Indian families. The ceramic tile manufacturing sector employs over half a million individuals, reflecting its significant economic role.

Strategic planning and market research enable businesses to tap into these business ideas and achieve substantial growth.

Ceramic tiles are segmented by application into residential, commercial, and replacement categories. The residential segment is experiencing the fastest growth, while the commercial segment is driven by organized retail and shopping mall construction. Diverse sales channels, including e-commerce and physical showrooms, enhance market reach and customer engagement.

Fluctuations in demand for ceramic tiles can lead to revenue volatility for manufacturers. Understanding market segmentation is critical for targeting different consumer needs and adapting business strategies to market conditions.

The price of ceramic tiles is influenced by quality, design, and production costs, typically ranging from $0.50 to $15 per square foot. Pricing strategies account for raw material costs and market demand, impacting the final retail price. Discounts and promotions are commonly used to attract customers and increase sales volume.

Installation costs typically add an additional $4 to $8 per square foot to the overall cost of ceramic tile projects. Tile pricing varies significantly between types such as ceramic, porcelain, and natural stone, with each category positioned differently in the market.

Achieving a competitive advantage in the ceramic tile industry involves focusing on profit margins, financial forecasts, and differentiation strategies. Profit margins can reach around 28%, depending on market conditions and operational efficiency. Companies must differentiate their products to maintain profit margins amid competition.

Leveraging innovative product designs and advanced manufacturing techniques enhances competitive position and achieves sustainable growth in the market.

Businesses in the ceramic tile sector must obtain necessary licenses, including BIS certification, to confirm adherence to safety and quality standards.

Compliance with regulatory requirements and adopting sustainable practices are crucial for maintaining operational licenses and meeting consumer expectations.

Establishing a ceramic tile manufacturing business requires obtaining several licenses, including a business license, GST registration, and environmental clearance. Specific operational permits may also be needed based on local legislation, such as fire department permits and safety compliance certifications. The application process typically involves submitting required documents, completing application forms, and possibly undergoing an inspection by regulatory authorities.

Following up on application status and providing additional information if required by the licensing authorities is essential. Regular audits and reporting are often necessary to maintain compliance with local and environmental regulations.

Technological innovations in the ceramic tile sector mitigate environmental challenges associated with production. Companies increasingly focus on developing eco-friendly products to cater to changing consumer preferences and contribute to sustainability efforts. The push for eco-friendly ceramic tiles reflects consumer demands and significantly contributes to the industry’s sustainability.

Increasing scrutiny over environmental impact pushes ceramic tile manufacturers to adopt sustainable practices and reduce their carbon footprint.

Strong brand presence and effective marketing strategies are essential for gaining a competitive advantage in the ceramic tile market. Leveraging product innovation, brand reputation, and efficient distribution networks enhances market position and reaches a broader audience.

Creating a strong brand identity involves:

Positioning ceramic tiles as lifestyle choices rather than mere products enhances brand appeal and consumer connection. Effective branding and positioning are critical for standing out in a competitive market and attracting loyal customers.

Sales channels are crucial in reaching customers and facilitating the marketing of ceramic tiles to various consumer segments. Showrooms provide a tactile experience for customers, allowing them to see and feel the tiles before making a purchase. Online platforms enable customers to browse, compare, and purchase tiles from the comfort of their homes, which is increasingly popular among consumers.

Distributors play a vital role in the supply chain, ensuring that ceramic tiles reach retailers and directly impact market penetration and availability.

Promotional activities are vital for enhancing sales and establishing a strong market presence. Incorporating interactive elements into advertisements can engage potential customers more effectively than static images alone. Engagement strategies focus on creating an emotional connection with potential customers, significantly boosting sales.

By utilizing high-quality visuals and social media platforms, businesses can effectively showcase their products and reach a broader audience.

Identifying and mitigating risks is crucial for the success of a ceramic tile manufacturing business. Market risks include fluctuating demand due to changing consumer preferences and increased competition from substitutes.

Operational risks can arise from supply chain disruptions and unexpected machinery breakdowns, which can halt production and delay deliveries.

The competitive landscape in the ceramic tile industry is evolving, with new entrants posing challenges to established businesses. Mitigation strategies include conducting regular market analysis to anticipate shifts in demand and developing flexible business strategies to adapt to market conditions.

Equipment malfunctions can hinder production efficiency, leading to increased operational costs and delays. Regular maintenance of machinery is essential to prevent unexpected breakdowns that can halt production.

By ensuring regular maintenance and adopting preventive measures, businesses can enhance production reliability and minimize operational disruptions.

Financial risks like cost overruns on production or unforeseen cash flow issues can threaten the financial stability of the manufacturing venture. Poor cash flow management can jeopardize operations; companies should maintain contingency funds to address short-term cash needs.

Implementing stringent budget controls and maintaining contingency funds can help mitigate financial risks and ensure operational stability.

Human resources are crucial in ensuring productivity and operational success in the ceramic tile manufacturing industry. With over 550,000 workers employed in the Indian ceramic tile industry, the large workforce supports manufacturing efficiency and overall production levels.

The ceramic tile industry employs approximately 50,000 direct employees and supports around 500,000 indirect jobs. Roles within a manufacturing plant include production operators, quality control inspectors, and maintenance staff, highlighting the diverse functions needed for efficient operations. Ensuring the right staffing levels and having a skilled workforce are critical for maintaining high production standards and meeting market demand.

Training programs for tile installers include a week-long course covering basic installation techniques and ANSI specifications. Hands-on training courses also prepare individuals for advanced techniques, such as shower installation and large format tile work.

Effective human resource management involves regular performance evaluations and employee engagement initiatives to boost productivity. Implementing performance evaluations can help identify training needs and enhance productivity within the workforce. Regular training and development programs ensure that employees stay updated with the latest industry practices and maintain high standards of work.

Effective human resource management practices are essential to optimize workforce productivity in a tile manufacturing plant. Continuous workforce development through tailored training initiatives helps in maintaining a skilled and motivated workforce. Emphasizing worker safety and retention strategies helps mitigate skill gaps and high turnover.

By implementing robust HR practices, businesses can ensure a productive and satisfied workforce, contributing to the overall success of the manufacturing operations.

Starting a ceramic tile manufacturing unit is a smart choice given the growing demand and favorable market conditions. Our project report will save you time, reduce risks, and increase your chances of success.

Take the first step today and embark on a rewarding business journey in the ceramic tile industry.

In summary, the ceramic tile manufacturing business offers immense potential for growth and profitability. By understanding the market trends, manufacturing processes, and financial aspects, you can make informed decisions and set up a successful venture. With our comprehensive project report, you are equipped with the knowledge and tools to navigate this lucrative industry confidently. Seize the opportunity and make your mark in the ceramic tile industry.

The main raw materials required for ceramic tile manufacturing are clay, feldspar, silica sand, and talc. These components are essential for producing durable and high-quality tiles.

To establish a ceramic tile manufacturing plant, an initial investment exceeding ₹25 million is required, covering machinery and infrastructure setup.

The key stages in the ceramic tile manufacturing process are raw material preparation, shaping, drying, glazing, and firing. Each stage is crucial in ensuring the final quality of the tiles produced.

Utilizing your project report offers the benefits of comprehensive cost analysis, in-depth technical details, and expert insights, which collectively save time, mitigate risks, and enhance the likelihood of project success.

This project report is highly beneficial for aspiring entrepreneurs, small-scale manufacturers, consultants, and students conducting industrial research. Consider obtaining it to enhance your understanding and insights in these areas.