Looking to start a Tur Dal mill business? This article provides a comprehensive Tur Dal mill project report, covering essential aspects like cost estimation, manufacturing processes, necessary permissions, and market opportunities. Whether you’re an aspiring entrepreneur or a seasoned business owner, you’ll find all the information you need to successfully set up and run a profitable Tur Dal mill.

Tur Dal, commonly known as Pigeon Pea, is a vital source of plant-based protein, making it an essential component of the Indian diet. Its high protein content supports muscle growth and repair, making it a crucial dietary element for both vegetarians and non-vegetarians alike. Additionally, the fiber in Tur Dal aids digestion and helps maintain heart health due to its low saturated fat content.

The dal milling industry ranks as the third-largest food processing sector in India. This highlights its considerable commercial significance. Maharashtra, Karnataka, and Uttar Pradesh are the leading producers of Tur Dal, although they face challenges such as erratic monsoons. The consistent demand for processed Tur Dal, driven by a rising population and changing dietary preferences, highlights the potential for growth in large scale dal industries. Pulse milling, which includes cleaning, dehusking, and splitting, plays a crucial role in meeting this demand and improving processing efficiency.

With the increasing consumption of Tur Dal, setting up a dal mill presents a lucrative entrepreneurial opportunity. The process not only supports local agriculture but also contributes to economic stability by creating jobs and fostering rural development. Engaging in the dal milling industry allows entrepreneurs to tap into a market with substantial demand and growth potential.

Establishing a Tur Dal mill in India necessitates adherence to various legal and regulatory requirements. Key licenses and registrations include business registration through the Ministry of Corporate Affairs or local authorities, GST registration for tax compliance, and obtaining an FSSAI license to ensure food safety standards. Consulting a legal or compliance expert can streamline the licensing process and help avoid potential delays.

Further essential permissions include a pollution control certificate from the State Pollution Control Board (SPCB) and a factory license from the local Factories and Boilers Department to ensure compliance with environmental and safety norms. For businesses involved in export or import, registering for an Import-Export Code (IEC) through the Directorate General of Foreign Trade (DGFT) is crucial.

Ensuring all documents, such as proof of business premises, bank account details, and worker employment records, are prepared and submitted on time is vital to avoid delays. Regularly checking for updates on regulatory changes in the agro-processing sector ensures ongoing compliance and smooth operation.

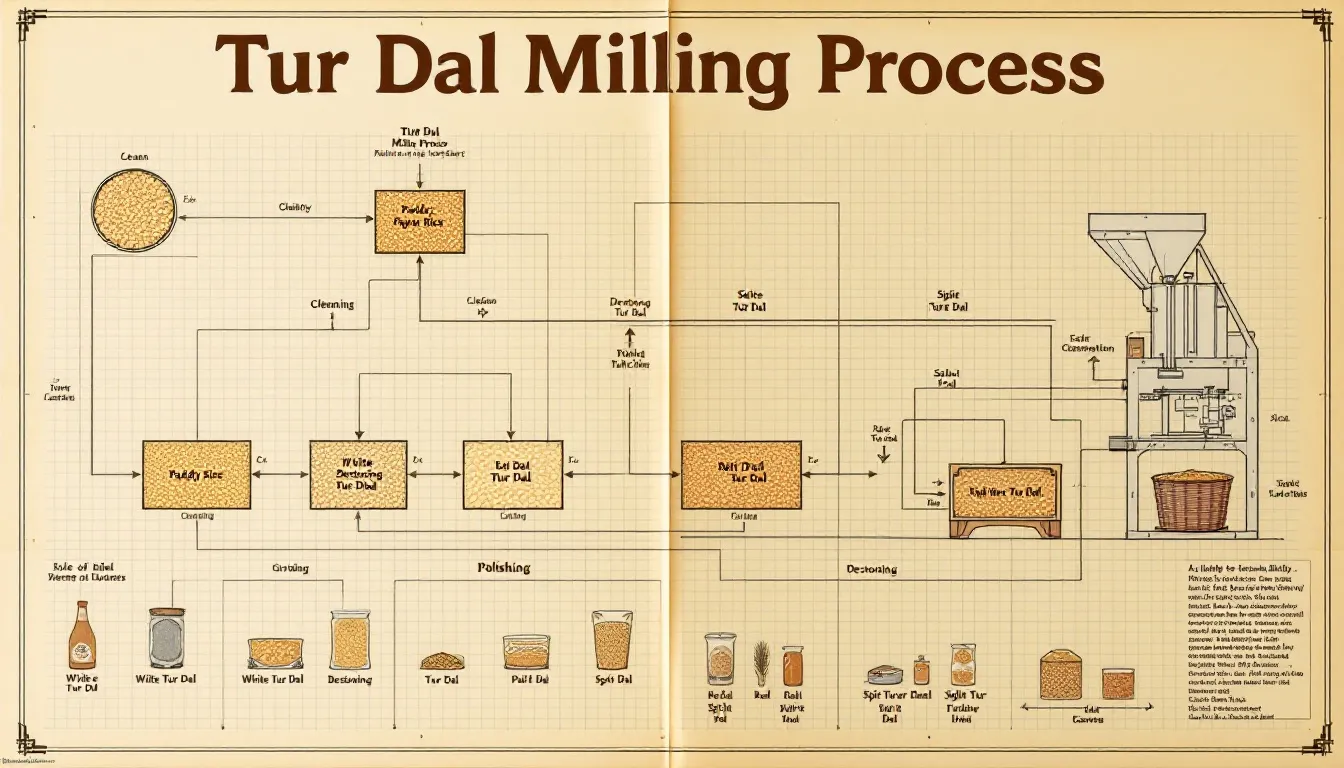

The manufacturing process of Tur Dal begins with pre-cleaning, where raw tur is purified to remove stones, dust, and other impurities using a de-stoner machine. This initial step is crucial for ensuring the quality of the final product. After pre-cleaning, the tur is dried to reduce its moisture content before being cooled to maintain the desired moisture level.

An effective method used in the dehusking and splitting process is alternate wetting, which involves repetitively soaking, drying, and tempering the pulses to achieve optimal moisture content before processing. This significantly enhances the yield and quality of the final product. De-husking is the next step, involving the removal of the outer shell of the tur by passing it through multiple hulls. The split process follows, breaking the tur grains into two equal halves, which are then graded based on size. Sorting machines, such as color sorters, ensure that only pure yellow grains are selected, discarding any green or other impurities.

The final product undergoes polishing according to customer specifications before being packaged for sale. This comprehensive process, from pre-cleaning to polishing, ensures that the milled dal meets high-quality standards and consumer expectations.

The production process of a Tur Dal mill is meticulously structured to ensure the highest quality output. The stages include pre-cleaning, de-husking, splitting, sorting, and polishing. Each step is vital in transforming raw tur into a clean, polished product ready for consumption and market distribution.

High-quality raw materials are essential for optimal yield and maintaining the nutritional value of the final product. The production chart not only outlines these steps but also emphasizes the importance of each phase in achieving a superior final product.

The primary raw materials required for milling Tur Dal include high-quality tur pulses. Selecting top-grade pulses ensures optimal processing and a desirable final product. Additional materials such as water and cleaning agents are also necessary during the milling process.

Sourcing raw materials from reputable suppliers and checking for quality certifications can greatly enhance the consistency and quality of the milling process. This step is crucial for maintaining the nutritional value and consumer appeal of the processed dal.

Setting up a Tur Dal mill involves procuring various types of machinery and equipment. Essential equipment includes de-stoners for pre-cleaning, emery rollers for de-husking, and pulse grading machines for sorting pulses based on size. Each piece of equipment plays a crucial role in different stages of the milling process.

The emery roller, for instance, is used for de husking pulses, while pulse grading machines sort the pulses at capacities ranging from 100 to 500 kg per hour. However, several machine parameters such as low capacity and specific pre-milling treatments restrict the performance of small-scale dal mills compared to large-scale mills. For optimal performance, dal mills usually require a three-phase motor with power ratings between 4 to 45 HP.

The construction materials for these machines, typically stainless steel and mild steel, ensure durability and longevity. Investing in high-quality equipment is essential for efficient milling operations and maintaining product quality.

Setting up a Tur Dal mill involves significant financial investment. The fixed capital requirements can total around Rs. 8,25,000, excluding land costs. The initial investment covers the cost of machinery, equipment, and infrastructure.

Monthly working capital is estimated at Rs. 15.5 lakh, which includes expenses for raw materials, wages, and receivables. Despite the high initial investment, the potential revenue is substantial, with annual earnings projected to be around Rs. 12.5 lakh based on the sale of processed dal.

Profit margins can exceed 40%, depending on operational efficiency and market prices. With a 70% capacity utilization, the annual output of a Tur Dal mill can be around 500 tons, highlighting the economic viability of this venture.

India accounts for approximately 72% of global Tur Dal production, indicating a strong market presence and substantial demand. The dal milling market in India is projected to grow at a rate of 12.3% from 2022 to 2027, driven by increasing consumption and changing dietary preferences.

West Bengal contributes significantly to pulse production and offers substantial government support and subsidies for setting up dal mills in the state.

Wholesale prices of Tur Dal in Indian markets have seen significant fluctuations, ranging between ₹11,000 and ₹19,000 per quintal in July 2024, with an average price of ₹15,291.7 per quintal. Government interventions, such as extending the free import policy for Tur and Urad Dal until March 2025 and imposing stock limits, aim to stabilize domestic prices and ensure availability.

Erratic weather patterns and diseases affecting crops have led to reduced domestic production, necessitating increased imports to meet demand. Tur Dal remains a staple in Indian diets, with significant consumption in both rural and urban households, underscoring its importance in the food basket.

Establishing a Tur Dal mill involves addressing various logistical challenges, such as ensuring a steady supply of raw materials and effective distribution channels. The initial investment in machinery and infrastructure can be substantial, making it crucial to conduct a thorough financial analysis.

Compliance with government regulations and obtaining necessary permits can pose significant hurdles for new dal mill projects. Hiring skilled labor is often a challenge, as specialized training may be required for efficient milling operations.

Market competition is another critical consideration, as new players must differentiate their products to attract customers. Seasonal fluctuations in the availability of raw materials can also affect production consistency and operational planning.

India is the world’s leading exporter of Toor Dal, with 88% of global exports totaling 14,721 shipments. The United States, Canada, and Singapore are the top three destinations for Toor Dal exports from India, collectively accounting for 73% of total exports.

India’s reliance on Tur Dal imports is significant, primarily sourcing from Mozambique, Malawi, and Myanmar. The removal of import duties and restrictions on Tur Dal from Mozambique by the Indian government aims to encourage imports and stabilize the domestic market.

The project report service enables entrepreneurs to create a detailed report for their Tur Dal mill project quickly, requiring minimal financial knowledge. Our experts can prepare a comprehensive project report designed to answer all possible questions related to starting a business.

A well-structured project report clarifies business objectives and plans, providing potential investors with detailed insights into the market analysis, technology, and financial feasibility of the Tur Dal milling business.

Preparing a comprehensive project report involves covering critical aspects such as site development, machinery needs, raw materials, and utility requirements. The report should also encompass industry insights, feasibility studies, and detailed financial projections to attract potential investors.

Including an industry introduction helps contextualize the project, while financial projections must outline estimated revenues, costs, and funding strategies to entice investors.

Understanding key financial metrics such as initial investment, ongoing operating costs, and potential revenue streams is crucial for attracting investors and securing loans. These metrics clarify the financial viability and growth potential of the business.

Project Report Bank offers a range of services, including downloadable project reports, to assist businesses in setting up a dal mill project report. Their reports provide detailed information on industry introduction, feasibility, manufacturing process, financial analysis, and other necessary components to attract investors.

Utilizing the services of Project Report Bank can streamline the process of setting up a business by providing expert insights and comprehensive guides, ensuring a successful and sustainable venture.

In summary, establishing a Tur Dal mill presents a lucrative opportunity, leveraging the increasing demand for nutritious and protein-rich food. From understanding the manufacturing process to navigating financial and regulatory requirements, this comprehensive guide provides the essential knowledge needed to embark on this venture.

By following the detailed project report and utilizing the services of Project Report Bank, entrepreneurs can confidently set up and operate a successful Tur Dal mill, contributing to economic stability and meeting the growing market demand.

To set up a Tur Dal mill, you must first secure the necessary permissions and licenses, including business registration, GST registration, and an FSSAI license. Then, procure high-quality raw materials and machinery. These steps are crucial for establishing a successful operation.

A Tur Dal mill requires de-stoners for pre-cleaning, emery rollers for de-husking, and pulse grading machines for sorting the pulses. This machinery ensures efficient processing and quality output.

The initial investment for a small Tur Dal mill is approximately Rs. 8,25,000, not including land costs, with an additional monthly working capital requirement of Rs. 15.5 lakh.

Profit margins in the Tur Dal milling business can exceed 40%, contingent upon operational efficiency and prevailing market prices, with potential annual revenue estimated at approximately Rs. 12.5 lakh.

Project Report Bank can significantly assist in setting up a Tur Dal mill by providing detailed project reports that encompass industry insights, feasibility studies, and financial projections, thus facilitating effective planning and execution.