Are you planning to set up a Bio CNG plant and need a comprehensive project report? This article offers a detailed guide on creating a bio CNG plant project report pdf. It includes essential elements like plant design, feasibility studies, financial projections, and regulatory compliance. Learn how to secure financing, obtain approvals, and ensure the success of your Bio CNG project.

A Bio CNG plant project report is indispensable for the successful establishment of a Bio CNG plant. It serves as a blueprint, guiding investors, regulatory bodies, and other stakeholders through the project’s intricacies. The report helps secure financing, obtain regulatory approvals, and ensure overall project success.

But what exactly is Bio CNG, and why is it gaining traction over conventional CNG and fossil fuels? Bio CNG, or Compressed Biogas, is produced by upgrading biogas to meet the quality standards of natural gas. This renewable energy source is derived from organic waste materials through a process called anaerobic digestion, making it a sustainable alternative to fossil fuels.

Unlike conventional CNG, Bio CNG offers numerous benefits, including reduced greenhouse gas emissions, enhanced waste management, and diverse applications in transportation, power generation, and more.

A Bio CNG plant project report typically includes several critical components. The executive summary provides a snapshot of the project, outlining its objectives, expected outcomes, and significance.

A feasibility study analyzes the availability of feedstock, seasonal variations, and transportation logistics, ensuring the project’s viability. Additionally, financial projections and environmental impact analyses are crucial for instilling investor confidence and ensuring regulatory compliance.

A detailed project report offers numerous advantages. It provides a comprehensive cost breakdown, essential for securing funding from investors. Moreover, Bio CNG production creates jobs in sectors like production, transportation, and distribution, thereby enhancing project success.

Diversifying energy sources through Bio CNG reduces risks and increases resilience, which is crucial for long-term sustainability.

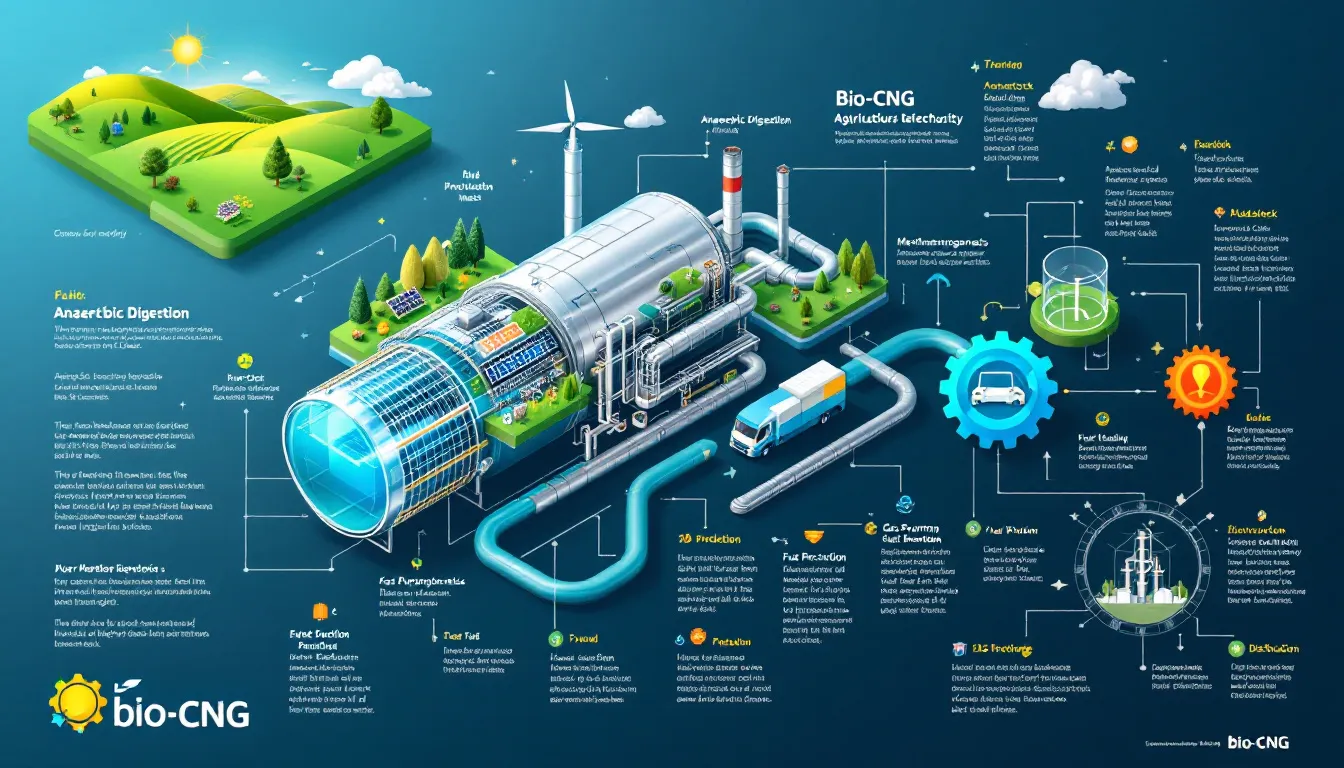

Bio CNG technology is a marvel of modern engineering, converting organic waste into a clean, renewable fuel. This process begins with anaerobic digestion, where organic materials are broken down by microorganisms in the absence of oxygen, producing biogas. The biogas is then purified and compressed to meet the quality standards of natural gas. Utilizing organic waste for Bio CNG production helps address waste management challenges and contributes to the circular economy.

The key processes involved in Bio CNG production include anaerobic digestion, biogas purification, and compression. Each of these stages is critical for ensuring the efficiency and quality of the final product. In the following subsections, we will delve deeper into each of these processes, shedding light on the technologies and techniques that make Bio CNG production possible.

Anaerobic digestion is the cornerstone of Bio CNG production, converting organic waste into biogas through microbial activity in oxygen-free environments. The main components of the biogas produced are methane (CH4) and carbon dioxide (CO2). Advanced technologies like Fixed Dome, Continuous Stirred Tank Reactor (CSTR), and DRYADTM are employed by various companies to enhance the efficiency of this process. Selecting the right technology is essential for maximizing biogas yield and operational efficiency.

FOV Biogas offers a range of digesters, from small-scale 1 m3 units to large-scale 1000 m3 systems, catering to different operational needs. Quantum Green and Kankyo are examples of companies utilizing advanced CSTR technology for effective digestion. This process not only generates biogas but also produces organic manure, which can be used as a valuable by-product in agriculture.

Biogas purification is a critical step in Bio CNG production, involving the removal of impurities to produce high-quality, clean energy. The primary goal is to separate methane from carbon dioxide and other contaminants, ensuring that the biogas meets the stringent standards required for compressed natural gas (CNG). This process not only enhances the energy content of the biogas but also makes it suitable for various applications, including power generation and transportation.

Once purified, the biogas is compressed to high pressures to produce compressed biogas (CBG). This step is essential for storing and transporting the biogas efficiently, making it a viable alternative to conventional fossil fuels.

Converting organic waste into clean, renewable energy, Bio CNG plants promote sustainable waste management and reduce greenhouse gas emissions.

The use of organic waste materials as feedstock is a cornerstone of Bio CNG production. Agricultural residues, food waste, animal manure, and municipal solid waste are among the primary sources of biogas. FOV Biogas installations utilize food waste, cow dung, and night soil as feedstock, reducing waste and supporting the circular economy by converting these materials into valuable energy.

Innovative techniques, such as Kankyo’s semi-aerobic hydrolysis process, enhance the efficiency of converting agricultural waste into biogas. Utilizing agricultural residues like wheat straw and rice straw not only helps manage waste but also provides additional income streams for farmers.

Incorporating diverse organic materials ensures a consistent and sustainable feedstock supply, contributing to the overall success of Bio CNG projects.

The market for Bio CNG is expanding rapidly, driven by the growing demand for sustainable energy solutions. Globally, the market is projected to grow significantly over the next decade, with substantial opportunities in both developed and developing countries.

In India, government initiatives and policies are fostering a favorable environment for Bio CNG production, addressing both energy needs and waste management challenges. Understanding demand and supply trends, key industry players, and market opportunities is crucial for the successful implementation of Bio CNG projects.

The availability and sourcing of raw materials and feedstock are critical for the viability of Bio CNG plants. Organic waste materials such as agricultural waste, dairy waste, and food waste are the primary feedstock. Developing a robust sourcing strategy ensures a consistent supply of these materials, which is essential for sustained biogas production.

Utilizing renewable energy sources like rice straw and other agricultural residues, Bio CNG plants reduce reliance on fossil fuels and contribute to a more sustainable energy landscape.

Conducting a thorough feasibility study is paramount for assessing the potential success and sustainability of a Bio CNG plant. This study evaluates various factors, including technology, policy environment, and economic aspects, to ensure the project’s viability. Analyzing feedstock availability, understanding seasonal changes, and logistics for transportation are essential components of the feasibility study.

A comprehensive feasibility study also includes market analysis, assessing demand, competition, and potential revenue streams. This involves evaluating the total production cost per unit and the revenue generated per unit, which are crucial for determining the economic feasibility of the project.

Thorough planning, from raw material procurement to regulatory compliance, is essential for the successful execution of a Bio CNG project.

Technical feasibility focuses on the practical aspects of implementing Bio CNG technology. Anaerobic digestion can be tailored to process various types of organic waste, enhancing its versatility. However, integrating advanced technology into existing systems and scaling operations can present challenges.

Ensuring compliance with environmental and safety regulations is also a critical aspect of technical feasibility.

Economic viability is a key consideration for Bio CNG projects. The total production cost of Bio CNG can range significantly, with real-world estimates around Rs 37-40 per kg. Revenue potential is substantial, with Bio CNG fetching Rs 46 per kg when sold to oil marketing companies, and potentially higher in private sales.

Key financial metrics such as Net Present Value (NPV) and Internal Rate of Return (IRR) are used to evaluate the investment’s attractiveness, with projected IRRs of 13-15% and payback periods of 4-5 years.

Market research is critical for understanding the growth potential and competitive landscape of the Bio CNG market. The global Bio CNG market is expected to grow from approximately USD 26.91 billion in 2023 to USD 42.69 billion by 2032. This growth is driven by the increasing demand for sustainable energy sources in transportation and other industries.

Analyzing local market demand and competition helps guide strategic decisions for plant expansion and capacity scaling.

Designing and planning a Bio CNG plant involves several critical steps to ensure operational efficiency and reliability. Reliable infrastructure, such as road access for biomass transport and waste removal, is essential for the plant’s success. Strategic planning and execution are necessary to enhance operational efficiency and ensure seamless project delivery.

Effective project execution requires a well-defined timeline that includes milestones for construction, commissioning, and operation. Coordinating construction, equipment installation, and staff training is crucial to ensure smooth operations from the start.

An effective layout design for a Bio CNG plant ensures that all major components are positioned for optimal efficiency. The layout should facilitate the seamless flow of materials and processes, enhancing overall operational efficiency.

For instance, a 5 TPD Bio CNG plant typically requires an area of approximately 500 m2, while a 100 TPD plant may need around 4-5 acres.

Selecting the ideal location for a Bio CNG plant is crucial for ensuring its operational success. The plant should be situated within a 15-kilometer radius of biomass sources to minimize transport costs and maximize efficiency. Additionally, the land area requirement varies based on the plant’s capacity, with larger plants requiring more space.

Infrastructure setup is another vital consideration. This includes storage facilities, transportation logistics, and power backup systems, all of which are essential for the smooth operation of the plant. Proper infrastructure ensures that the plant can handle the feedstock efficiently and maintain consistent production levels.

Effective feedstock management is pivotal for the consistent operation of a Bio CNG plant. A diverse range of organic materials, such as food waste and agricultural residues, can be used as feedstock. Raw material procurement represents a significant recurring expense, making long-term contracts with suppliers crucial for reliability.

Incorporating high-yielding crops like Napier Grass into the feedstock strategy can further enhance the plant’s capacity.

Operational efficiency is essential for the success of a Bio CNG plant. A well-structured operational plan, including feedstock collection, biogas production, and maintenance schedules, is vital. Regular monitoring of operational parameters and utilizing real-time data analytics can significantly improve performance tracking and optimization.

Establishing a routine preventive maintenance schedule is also crucial to minimize downtime and prolong equipment lifespan.

Cost estimation and financial projections are critical components of a Bio CNG plant project report. Setting up a Bio CNG plant typically involves a significant initial capital outlay. Market research should focus on the fluctuating costs of feedstock, which significantly affect overall production costs. Detailed projections in the project report help in assessing profitability and long-term financial sustainability.

Accurate cost estimation includes both initial investment and operating costs. Initial investment breakdown covers the capital costs for setting up the plant, while operating costs include recurring expenses like maintenance, labor, and feedstock procurement.

The initial investment for setting up a Bio CNG plant can range from Rs 2 crore to Rs 10 crore, depending on the plant’s capacity and technology used. For example, the capital cost for a 2 TPD biogas plant offered by Ahuja Engineering is Rs 40 lakhs, while a 100 TPD plant developed by SLPP Re-New is approximately Rs 15 crores.

These estimates provide a clear understanding of the financial commitment required for establishing a Bio CNG plant.

Operating costs are a major consideration for the financial viability of a Bio CNG plant. Recurring expenses include maintenance costs, which are essential for ensuring smooth operation and regular inspections and repairs. Labor costs encompass salaries for skilled operators and technicians who manage and maintain plant operations.

Feedstock procurement is another significant recurring cost that must be managed effectively to maintain production levels.

Financial projections are essential for assessing the long-term profitability of a Bio CNG plant. These projections should include revenues and operating expenses over the plant’s lifetime to evaluate profitability.

Payback periods, which indicate the duration required to recover the initial investment, are crucial for attracting investors, with shorter periods generally preferred.

Ensuring regulatory compliance is crucial for the successful establishment and operation of Bio CNG plants. In India, Bio CNG plants must adhere to Environmental Impact Assessment (EIA) regulations and standards set by national and local environmental authorities. A comprehensive project report can enhance the likelihood of receiving government subsidies and grants, attracting investors, and meeting legal requirements.

Bio CNG plants have a positive environmental impact, significantly reducing landfill waste and greenhouse gas emissions. By converting waste into valuable energy, these plants support better waste management solutions and contribute to climate change mitigation.

The government offers various financial incentives for renewable energy projects, including grants and subsidies for Bio CNG plants. The Ministry of New and Renewable Energy facilitates a biogas program that includes setting up biogas plants for clean and renewable energy production.

Securing a Consent to Establish from the State Pollution Control Board is mandatory for initiating a Bio CNG project.

Bio CNG plants offer numerous environmental benefits. Utilizing municipal solid waste in Bio CNG production helps alleviate landfill issues and supports waste management. These plants significantly reduce landfill waste, decreasing the likelihood of methane emissions associated with waste decomposition. Converting waste into valuable energy, Bio CNG production supports better air quality and reduces harmful emissions.

Additionally, Bio CNG plants contribute to climate change mitigation by significantly reducing greenhouse gas emissions. Decreasing the carbon footprint of power generation is one of the environmental advantages of biogas production, making Bio CNG a sustainable alternative to conventional fossil fuels.

Sustainability practices in Bio CNG plants focus on reducing environmental impact and promoting renewable energy solutions. These practices include reducing greenhouse gas emissions, improving waste management processes, and supporting the circular economy.

Implementing sustainable practices, Bio CNG plants contribute to a more sustainable future.

Implementing a Bio CNG project requires careful planning and execution. Successful projects involve comprehensive site analysis, equipment selection, and execution strategies. Consistent feedstock sourcing, technology upgrades, and stakeholder collaboration are essential for sustained success in Bio CNG production.

The following subsections provide practical steps for site selection, plant and machinery requirements, and project execution, ensuring a smooth and efficient implementation process.

Selecting the right site for a Bio CNG plant is critical for ensuring operational success and economic viability. The location should be within a 15-kilometer radius of biomass sources to minimize transport costs and maximize efficiency. Proximity to feedstock sources is crucial for maintaining a consistent supply and reducing logistical challenges.

The capacity and efficiency of machinery are crucial factors when procuring equipment for large-scale Bio CNG production. It is beneficial to consider suppliers that provide after-sales support and maintenance services to ensure sustained operation of the plant.

Essential machinery includes biogas digesters, purification units, storage systems, and filling stations, with detailed cost estimations for each component.

A detailed project timeline is essential for streamlining project execution. This timeline should outline all phases of construction, equipment installation, and operational startup, ensuring that each step is completed on schedule.

Effective project execution requires meticulous planning and coordination to achieve optimal performance and successful project delivery.

Ensuring long-term success and optimization of a Bio CNG plant involves continuous improvement processes and performance monitoring. Effective design and planning are essential to maximize operational efficiency and productivity. Implementing sustainable practices and adapting to new technologies can significantly enhance the plant’s efficiency and sustainability.

Regular performance monitoring allows for real-time assessment of operations, helping identify areas for growth and optimization. Establishing routine maintenance best practices prevents downtime and ensures the consistent performance of plant operations.

Regular monitoring of emissions and adherence to safety standards are essential sustainability practices for Bio CNG operations. Effectively tracking and analyzing performance data allows Bio CNG plants to continuously improve their operations and sustainability efforts.

Performance monitoring ensures that the plant operates efficiently and meets regulatory standards.

Implementing energy-efficient technologies in Bio CNG plants can lead to reduced operational costs and improved sustainability. Regular maintenance is crucial for ensuring optimal performance and longevity of the plant.

These technologies not only enhance performance but also support the environmental sustainability goals of Bio CNG operations. Continuous maintenance ensures that the plant operates at peak efficiency, leading to significant cost savings over time.

Implementing effective strategies for scaling operations can significantly increase production capacity and operational efficiency in a Bio CNG plant. Regular performance monitoring allows for real-time assessment of operations, helping identify areas for growth and optimization.

Establishing routine maintenance best practices prevents downtime and ensures the consistent performance of plant operations.

In conclusion, Bio CNG technology represents a sustainable solution for waste management and renewable energy production. From understanding the importance of a comprehensive project report to exploring the technical, economic, and regulatory aspects, this guide provides a roadmap for establishing and operating a successful Bio CNG plant. By implementing best practices in design, planning, and maintenance, and leveraging government incentives, Bio CNG projects can achieve long-term success and contribute to a sustainable future.

Bio CNG is a renewable alternative to conventional CNG, as it is produced by upgrading biogas instead of being derived from fossil fuels. This differentiates it by offering a more sustainable energy source.

A Bio CNG plant project report must include an executive summary, feasibility study, financial projections, and an environmental impact analysis to ensure comprehensive evaluation and planning. These components are essential for assessing the project’s viability and sustainability.

Anaerobic digestion significantly contributes to Bio CNG production by breaking down organic waste in an oxygen-free environment, resulting in biogas that can be purified and compressed into Bio CNG. This process not only produces renewable energy but also manages waste effectively.

Bio CNG plants significantly reduce landfill waste and greenhouse gas emissions while converting waste into valuable energy. This process enhances air quality and aids in climate change mitigation.

When selecting a site for a Bio CNG plant, ensure it is within a 15-kilometer radius of biomass sources to reduce transport costs and maintain a consistent feedstock supply. Proximity to potential suppliers is a key factor for economic viability.