Unlock Your 3D Printing Potential with Our Expert Guide

Table of Contents

Starting a 3D Printing Business in India: Comprehensive Guide (2026)

Thinking about starting a 3D printing business in India? With 3D printing technology, businesses can create items featuring complex designs, enabling the production of intricate and innovative products across various industries. The industry is booming and this guide covers the market potential, benefits, and steps to get started.

Key Takeaways

The Indian 3D printing market is rapidly growing, with projected revenues reaching USD 314 million by 2030 and significant government support for the sector.

Starting a 3D printing business in India is advantageous due to low initial costs, high profit margins, and a focus on sustainable manufacturing practices.

Key steps to launching a successful 3D printing business include thorough market research, creating a robust business plan, and selecting appropriate technology for niche markets.

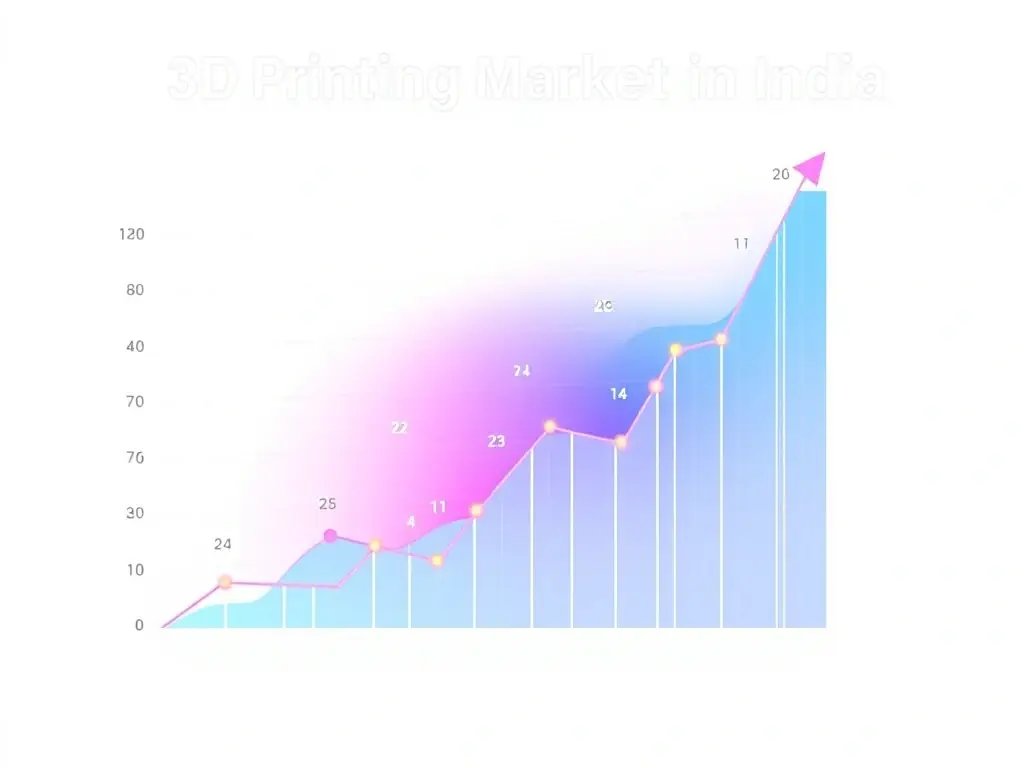

Understanding the 3D Printing Market in India

The 3D printing market in India is experiencing a meteoric rise with the following key points:

In 2023, it generated a revenue of USD 61.4 million.

Hardware is the largest revenue segment, accounting for approximately 66.29% of the total earnings.

The market is expected to grow to USD 314 million by 2030.

The compound annual growth rate (CAGR) is projected at 26.3%.

India currently holds a 0.3% share of the global market, indicating immense potential for growth.

The Indian government is implementing a national strategy to bolster the sector.

This strategy aims to enhance collaboration among academia, government, and industry.

One of the most exciting aspects of the Indian 3D printing market is its diversity. From medical devices to custom jewelry, the industry offers various niches for developing a business. Custom jewelry manufacturing, in particular, is emerging as a rapidly growing niche within the Indian 3D printing market, driven by increasing demand for personalized and intricate designs. Entrepreneurs and small businesses can use 3D printing to quickly test ideas by prototyping and iterating designs before moving to mass production. 3D printers utilize pre-programmed shapes to produce intricate and customized products, which is especially valuable for small businesses looking to offer unique solutions. State-specific subsidies further support MSMEs in acquiring the necessary technology and infrastructure.

With the hardware segment poised for the fastest growth in the coming years, now is an opportune time to dive into this growing market.

Benefits of Starting a 3D Printing Business in India

Starting a 3D printing business in India offers numerous benefits that make it an attractive venture:

Low initial cost, especially for home-based businesses, which can lead to good profits.

Various profitable business models that can result in quick returns on investment.

Low investment combined with high margins.

Growing demand for 3D printed products.

With these factors, the potential for success is substantial.

Sustainability is another significant benefit of 3D printing technologies:

They produce little to no waste, aligning with sustainable manufacturing practices.

Various biodegradable or recyclable filaments are available, offering environmental benefits.

3D printing requires less energy compared to traditional industrial production lines, enhancing operational efficiency.

With the ability to create custom products at reduced costs, 3D printing increases profit margins and operational flexibility. It also enables mass customization, allowing businesses to efficiently produce personalized products for different customers.

Step-by-Step Guide to Starting Your 3D Printing Business

Starting a 3D printing business involves several critical steps, each contributing to the foundation of a successful venture. The initial steps include:

Conducting thorough market research

Creating a detailed business plan

Completing business registration: This crucial legal step involves selecting a legal structure for your business and ensuring compliance with all necessary licensing requirements. Offering a limited range of services initially helps build experience and gather valuable customer feedback. Registering trademarks is also important to protect your brand identity. Additionally, intellectual property protection is essential for safeguarding unique designs and innovations in the 3D printing business.

Consistent quality, timely delivery, and excellent customer service are vital for growth. Let’s delve deeper into these essential steps.

Conduct Market Research

Conducting market research is the cornerstone of any successful business. To identify what to produce and where the demand lies, consider the following steps:

Examine local and online markets.

Identify gaps in the market.

Understand customer needs.

Analyze competitor prices.

Conduct a competitive analysis to evaluate the strengths and weaknesses of existing 3D printing businesses in your target market.

Define your niche and target market to ensure your offerings align with customer expectations.

Connecting with community groups and catering to existing local demand helps distinguish you from competitors. Integrating these insights into your business plan is essential for a strong start.

Create a Business Plan

A well-crafted business plan is your roadmap to success. It should include:

Your vision

Mission

Goals

Ideal customers

Industry analysis

Project needs

Budget

Choosing a memorable and fitting brand name is crucial, and trademark registration can protect it legally. Financial forecasts can attract potential investors, while tracking inventory and production costs ensures smooth operations.

Combining product sales with educational workshops—and explicitly offering classes—can be a viable business model to diversify your income and position yourself as a local expert.

Register Your Business

Registering your business involves navigating several legal and administrative steps. The GST registration threshold for 3D printing businesses in India is Rs. 20 lakhs (or Rs. 10 lakhs in special states). GST applies not only to the sale of 3D printed products but also to services related to 3D printing, and these services are taxed under the GST system. Obtaining a Trade License costs between Rs. 1,000 – Rs. 5,000 yearly.

MSME Udyam registration is important for accessing various government schemes and benefits. Legal consultation is advisable to ensure compliance with all requirements. Necessary licenses include:

MSME registration

GST registration

Local trade license Optional certification:

ISO certification

Choosing a Niche for Your 3D Printing Business

Selecting the right niche is a foundational step for any profitable business in the 3D printing industry. With the market becoming increasingly competitive, focusing your 3D printing business on a specific area allows you to develop specialized technical expertise and stand out from other 3D printing businesses. Popular niches include custom phone cases, medical prosthetics, dental models, intricate jewelry, home decor, and architectural models. Each of these areas is experiencing rising demand for 3D printed solutions due to their need for customization and rapid prototyping.

Conducting thorough market research is essential to identify gaps in the market and understand what potential customers are looking for. Analyze the competition, assess your own skills, and consider which industries align best with your interests and capabilities. By honing in on a niche, your printing business can deliver targeted solutions, build a strong reputation, and create a loyal customer base. This focused approach not only increases your chances of success but also helps you create a sustainable and profitable business in the ever-evolving world of 3D printing.

Business Model and Structure Options

When starting a 3D printing business, choosing the right business model and structure is key to long-term success. There are several options to consider, each with its own advantages. A service-based business model involves offering 3D printing services to clients, such as rapid prototyping, custom part manufacturing, or design services. B2B services—such as providing rapid prototyping or custom part manufacturing for other businesses—can be a lucrative business model. This approach is ideal if you want to work closely with customers and provide tailored solutions.

Alternatively, a product-based business focuses on designing, producing, and selling your own 3D printed products, such as consumer goods, custom nameplates, or educational tools. Some 3D printing businesses adopt a hybrid model, combining both services and product sales to diversify revenue streams. Subscription-based models are also gaining popularity, where customers pay a monthly fee for access to exclusive designs, priority printing, or ongoing support.

When selecting your business model, consider your available resources, target market, and the level of competition in your chosen niche. Developing a comprehensive business plan is essential—it should outline your goals, strategies, and financial projections. A well-structured business plan not only guides your decision-making but also helps attract investors and ensures your 3D printing business is built for growth and resilience.

Educational Resources for 3D Printing Entrepreneurs

Staying ahead in the 3D printing industry requires continuous learning and skill development. Fortunately, there are a wealth of educational resources available to help entrepreneurs enhance their technical expertise and improve print quality. Online courses are a great starting point, covering essential topics such as CAD software, advanced printing techniques, and material selection. Platforms like Coursera, Udemy, and LinkedIn Learning offer courses tailored to different skill levels. Certification programs in 3D printing technologies can provide formal recognition of your skills and enhance your credibility in the industry.

In addition to formal courses, YouTube tutorials and online forums provide practical, real-world advice on troubleshooting, optimizing print settings, and experimenting with new materials. Participating in 3D printing communities and attending industry workshops or conferences can also expand your network and keep you informed about the latest trends and innovations.

By investing in your education and staying up-to-date with the latest advancements, you can ensure your 3D printing business remains competitive, delivers high-quality results, and adapts to the evolving needs of your customers.

Choosing the Right 3D Printing Technology

Choosing the right 3D printing technology is pivotal for your business. Factors to guide your decision include:

Niche

Desired product type

Precision requirements

Speed requirements

Budget

Compatibility with materials

If you are new to the 3D printing business, an entry level printer is a cost-effective and beginner-friendly option to get started.

For businesses aiming to create prototypes and functional parts, investing in larger and more specialized industrial printers is advisable. Advanced printers with specialized features may be required based on your specific business model.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is renowned for its cost-effectiveness, making it ideal for both concept and functional prototypes. FDM printers are suitable for businesses requiring quick iteration for product designs, particularly in the consumer goods sector. FDM printing often requires support structures to successfully print complex geometries.

Profitable business opportunities utilizing FDM technology include 3D printing prototypes, manufacturing components, local 3D printing services, and 3D printing toys.

Stereolithography (SLA) and Digital Light Processing (DLP)

Stereolithography (SLA) and Digital Light Processing (DLP) are both resin printing technologies that offer high-resolution prints and faster production speeds, respectively. SLA uses a laser to cure resin, making it ideal for detailed prototypes, while DLP is suitable for mass-producing items with uniform quality. Both technologies use photopolymer resin as the primary material for creating high-resolution prints.

Industries like jewelry and dental benefit from these technologies in different industries due to their precision and efficiency.

Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS)

Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS) are both types of powder bed fusion technologies, which use a laser to fuse powdered materials into solid parts.

SLS and DMLS are advanced technologies used for creating durable, functional parts with complex geometries. SLS is particularly suited for nylon or polymer parts, while DMLS focuses on metal parts, resulting in high-density and highly detailed components.

These technologies are extensively used in industries for rapid prototyping, tooling, and end-use production parts.

Essential Equipment and Materials

Setting up a 3D printing business requires essential equipment and materials. This includes 3D printers, printing materials, and post-processing equipment. Custom miniatures for tabletop RPGs and collectibles, along with product-based businesses and R&D partners, represent potential customer profiles for a 3D printing prototyping service. Ensuring a well-ventilated workspace with a proper ventilation system to maintain air quality and ensure safe operation during post-processing is crucial.

3D Printers

There are various types of 3D printers available, including:

Entry-level printers: Designed for ease of use and affordability, making them ideal for beginners.

Mid-range 3D printers: Offer advanced capabilities suitable for commercial applications.

Industrial-grade machines: Provide precision and durability required for industrial use.

When selecting a 3D printer, consider factors such as budget, purpose, warranty, customer support, and build volume. Build volume determines the maximum size of objects you can print, which is crucial if you plan to create larger models.

Printing Materials

Printing materials are the lifeblood of any 3D printing business. Common filaments used in FDM include:

ABS

PLA

PETG These are popular for both prototyping and functional applications. Different materials like nylon and resin are chosen based on the project’s requirements.

Raw materials include plastic filaments, resin materials, metal powders, and photopolymers, as well as other materials. Staying updated on new materials and collaborating with researchers can enhance material options.

Post-Processing Equipment

Post-processing is often necessary to enhance the finish and quality of 3D printed products. Automating this process can save time and improve product quality. Sanding and filing tools, curing chambers, and cleaning stations are essential equipment for post-processing. Surface finishing techniques, such as polishing or coating, can further enhance the appearance and durability of 3D printed products. These tools play a critical role in achieving the desired finish and quality. Investing in these tools can range widely in cost but is crucial for achieving a professional finish.

Investment, Cost, and Profit Analysis

Understanding the financial landscape is critical for establishing a 3D printing business. For a small business, careful financial planning and resource allocation are essential to manage startup costs, marketing expenses, and legal requirements effectively. This includes knowing your budget, physical space requirements, and leveraging government subsidies tailored for MSMEs.

Selecting the right 3D printing technology aligns with specific market needs, focusing on product type and required output quality. The investment, cost, and profit analysis will provide insights for small, medium, and large-scale setups.

Initial Investment

Startup costs for a 3D printing business can vary widely, from a few hundred dollars to tens of thousands for industrial setups. Industrial-grade setups can cost $25,000 or more. Generally, starting a 3D printing business costs between $1,000 to $10,000. Main costs include:

3D printers

Materials

Software

Legal services

Marketing fees.

When planning your finances, remember to account for equipment depreciation, as 3D printers and related hardware lose value over time.

Quality printing materials can account for 10% to 20% of startup costs. Funding options like the Credit Guarantee Scheme can help mitigate high initial investments. Additionally, investing in quality printing material can enhance overall business presentation.

Operating Costs

Operating costs include raw materials, maintenance, and unexpected repair expenses. Material costs can significantly affect the overall budget. Labor costs, including salaries, benefits, and training, should also be considered. Effective inventory management can help control material usage, reduce waste, and optimize operating costs.

Implementing an on-demand production process system can minimize waste and improve financial efficiency while also reducing production time.

Profitability

Achieving profitability in a 3D printing business involves:

Targeting niche markets with high demand for specialized products.

Focusing on products like custom parts, medical devices, and jewelry that tend to command higher profit margins.

Considering material costs, equipment expenses, and market demand when setting pricing strategies.

Reinvesting profits into equipment upgrades and expanding capabilities for long-term success.

An on-demand production system helps minimize resource waste and maintain financial conservativeness.

Sustainability and Environmental Impact

Sustainability is rapidly becoming a key differentiator for any modern 3D printing business. Additive manufacturing technology, at its core, is designed to minimize waste by building products layer by layer, using only the exact amount of material required. Unlike traditional manufacturing, which often results in significant material loss, 3D printing and other additive manufacturing methods dramatically reduce environmental impact.

A forward-thinking business model can further enhance sustainability by incorporating recycled or biodegradable printing materials. For example, many 3D printing businesses now offer products made from PLA, a biodegradable filament derived from renewable resources, or use recycled plastics to create new items. These choices not only lower the carbon footprint of your printing business but also appeal to environmentally conscious customers seeking responsible solutions.

Additionally, additive manufacturing typically consumes less energy than conventional production lines, especially when optimized for efficiency. By adopting sustainable practices—such as sourcing eco-friendly raw materials, optimizing print settings to reduce energy use, and recycling failed prints—a 3D printing business can position itself as a leader in green manufacturing. This approach not only benefits the environment but also meets the rising demand for sustainable products and services, making your business more attractive in a competitive market.

Efficiency and Productivity

Maximizing efficiency and productivity is essential for any 3D printing business aiming to thrive in a growing market. Leveraging advanced additive manufacturing technologies like fused deposition modeling (FDM) and digital light processing (DLP) enables rapid prototyping and streamlined production, helping businesses deliver high-quality results with shorter production times.

Investing in industrial printers and robust CAD software can significantly improve print quality and output consistency. A dedicated workspace, equipped with proper ventilation, lighting, and regular equipment maintenance, ensures that your production process runs smoothly and safely. By optimizing your workflow and maintaining your equipment, you can achieve consistent quality across all projects.

Reducing material costs is another key factor in boosting profitability. Careful selection of printing materials and efficient use of resources can help minimize waste and lower expenses. Offering design services, hosting classes, and participating in trade shows are excellent ways to diversify your business, attract new customers, and stay ahead of industry trends.

By continuously refining your production process and adopting the latest additive manufacturing technologies, your 3D printing business can increase productivity, reduce costs, and deliver superior products. This commitment to efficiency not only enhances your reputation for consistent quality but also positions your business for long-term success in the competitive world of 3D printing.

Marketing and Sales Strategies

Marketing and sales strategies are crucial for the success of your 3D printing business. Key points include:

Highlighting unique selling points to differentiate you in a competitive market.

Engaging with social media platforms to enhance visibility and appeal.

Using platforms like TikTok and Instagram Reels for direct-to-consumer marketing.

Utilizing LinkedIn and YouTube for business-to-business marketing.

Establishing your own website for selling products and engaging customers, while also leveraging other platforms and social media channels to reach a wider audience.

Implementing lead generation strategies, such as offering free design consultations or downloadable resources, to attract potential customers.

Utilizing storytelling and visual content is vital for effective marketing. Strategies include B2B marketing, social media campaigns, and participation in trade expos.

Building an Online Presence

An online presence is crucial for attracting traffic, building trust, and fostering a community around your online business brand. Using an all-in-one eCommerce platform like Shopify can streamline the process of building a dedicated workspace for your 3D printing business and enhance your reach to online stores.

Platforms such as Instagram and Pinterest are effective for showcasing visually attractive 3D printed products to potential clients. Creating valuable content, such as blogs and tutorials, positions your business as an authority in the industry. Implementing search engine optimization (SEO) techniques can help your website rank higher in search results and attract more visitors.

Local Networking

Local networking is essential for expanding your customer base and building strong relationships in the local market. Participating in trade shows is a powerful strategy for building networks and enhancing brand visibility. Combining online visibility with local businesses engagement increases customer reach and overall effectiveness. Forming partnerships with educational institutions can help you access new customer segments and enhance your reputation in the community.

This balanced approach ensures a growing path for your business.

Educational and Promotional Events

Educational and promotional events can significantly attract new customers. Showcasing 3D printing in-person can spark interest and attract new customers. Offering workshops can educate customers and showcase the possibilities of 3D printing, attracting more business.

These events serve as powerful marketing tools to demonstrate the capabilities and applications of 3D printing technology.

Customer Service and Support Strategies

Exceptional customer service is a cornerstone of any successful 3D printing business. Building strong relationships with your customers starts with prompt, clear communication—whether through email, phone, or live chat. Providing personalized support, such as helping clients choose the right printing material or offering guidance on post processing equipment, can set your business apart from competitors.

Consider offering value-added services like design consultations, troubleshooting assistance, and detailed product information to enhance the customer experience. Proactively addressing any issues and following up after sales demonstrates your commitment to customer satisfaction. Implementing a customer feedback system can help you gather insights and continuously improve your service offerings. By prioritizing customer service and support, your 3D printing business can build trust, encourage repeat business, and benefit from positive word-of-mouth referrals.

Quality Control and Assurance in 3D Printing

Delivering consistent quality is essential for building a reputable 3D printing business. Implementing a robust quality control process ensures that every product meets your standards and customer expectations. This involves inspecting 3D printed items for defects, verifying dimensions, and assessing overall print quality. Using high-quality printing materials and advanced printing techniques further enhances the reliability and durability of your products.

Investing in industrial-grade printers and developing a comprehensive quality assurance plan can help maintain consistent quality across all projects. Implementing a quality management system can standardize processes and ensure consistent results. This plan should detail your quality control procedures, material selection criteria, and steps for continuous improvement. By making quality control and assurance a priority, your 3D printing business can deliver superior products, foster customer loyalty, and maintain a strong position in the competitive printing business landscape.

Government Schemes and Support

Government schemes and support play a critical role in easing the financial burden for new 3D printing ventures. The Startup India recognition, Credit Guarantee Scheme, and state subsidies under MSME & Innovation Mission provide substantial financial assistance. Technology incubation centers also provide startups with access to advanced equipment, mentorship, and networking opportunities. These schemes make it easier to establish and grow a 3D printing business in India.

Startup India Recognition

The Startup India initiative aims to promote innovation and entrepreneurship in the country, providing a supportive ecosystem for startups and encouraging new ideas and new business.

Startups need to register online on the Startup India portal and submit the required documents to apply.

Credit Guarantee Scheme

The Credit Guarantee Scheme aims to facilitate access to credit for MSMEs in India by providing guarantees for loans taken to purchase machinery. Applicants must be MSMEs duly registered and meet specific eligibility criteria set by the Government of India to qualify.

Financial support under this scheme enables businesses to upgrade their production capabilities.

State Subsidies

Several states in India provide financial assistance to encourage technology startups in fields such as 3D printing. State governments offer various incentives, including grants, tax exemptions, and capital investment subsidies.

Many MSMEs involved in 3D printing can access dedicated support programs offering tailored financial assistance and advisory services.

Challenges and Future Trends

The 3D printing industry faces several challenges, including material costs, the need for design skills, and competitive pressure. Another significant challenge is the risk of intellectual property theft, making it crucial to protect your designs. However, the future is bright with rising demand for 3D-printed jewelry, which is projected to reach $3.3 billion by 2030.

Technologies like SLS and DMLS are advancing, enabling the production of complex geometries and lightweight components for industries such as aerospace and automotive.

Overcoming Common Challenges

Starting a 3D printing business involves navigating several common challenges, including material costs, design skills, and competition. To start a 3D printing business, tackling high material costs involves collaborating with suppliers for bulk deals or selecting less expensive materials that maintain quality standards.

Enhancing design skills through training and hiring skilled designers with technical expertise can give you a competitive edge.

Future Trends in 3D Printing

Looking ahead, bioprinting is emerging as a vital area, focusing on creating living tissues for medical applications and revolutionizing regenerative medicine. Advancements in metal 3D printing are enhancing the range of alloys used, resulting in more precise and durable components for various industries.

These advancements are expected to enhance the speed and precision of 3D printing and additive manufacturing technology, making it more viable for mass production. Additionally, distributed manufacturing—where production is decentralized and closer to end users—is becoming increasingly feasible with 3D printing technology. The ability to 3d print will further support these improvements.

Summary

Starting a 3D printing business in India presents a unique opportunity to be at the forefront of a manufacturing revolution. From understanding the market to navigating government support, this guide has covered all the essential steps. By leveraging the right technology, materials, and marketing strategies, you can build a profitable and sustainable business. The future is bright for 3D printing in India, and now is the perfect time to dive in and make your mark in this innovative industry.

Frequently Asked Questions

What are the initial steps to start a 3D printing business in India?

To successfully start a 3D printing business in India, it’s essential to conduct thorough market research, develop a solid business plan, and register your business. These foundational steps will set the stage for your venture’s growth and success.

What are the benefits of starting a 3D printing business in India?

Starting a 3D printing business in India offers low initial costs, high profit margins, and sustainability, along with operational flexibility and diverse business models. These advantages position entrepreneurs for successful growth in a dynamic market.

What types of 3D printing technologies are available?

There are several types of 3D printing technologies available, including Fused Deposition Modeling (FDM), Stereolithography (SLA), Digital Light Processing (DLP), Selective Laser Sintering (SLS), and Direct Metal Laser Sintering (DMLS). Each technology offers unique advantages for different applications.

What are the essential equipment and materials needed for a 3D printing business?

To successfully establish a 3D printing business, essential equipment includes 3D printers, various printing materials like filaments and resins, and post-processing tools. This combination ensures you can produce high-quality prints and meet diverse customer needs.

What government schemes and support are available for 3D printing businesses in India?

For 3D printing businesses in India, various government schemes such as Startup India recognition, the Credit Guarantee Scheme, and state subsidies under the MSME & Innovation Mission provide essential support and financial assistance. These initiatives can significantly aid in growth and innovation within the sector.

Get Your Guide Now

Unlock Your 3D Printing Potential with Our Expert Guide

Expert Insights and Market Analysis

Step-by-Step Guidance for Success

Maximize Your Investment Potential

What Our Readers Say

-

eBook AI Manufacturing Ideas

₹500 -

eBook White Label Business

₹500 -

eBook Indian Jewellery Business

₹500 -

eBook Imitation Jewellery Business

₹500 -

eBook Diamond Gemstone Jewellery

₹500 -

eBook Jewellery Franchise

₹500 -

eBook Jewellery Export

₹500 -

eBook Lab Grown Diamond

₹500 -

eBook Medical Devices Manufacturing

₹500 -

eBook Ayurvedic Cosmetic

₹500 -

eBook 3D Printing Business

₹500 -

eBook Rare Earth Magnet Recycling

₹500 -

eBook Gold Refining Business

₹500 -

eBook Drone Parts Manufacturing

₹500 -

eBook Moduler Funiture

₹500 -

eBook on Future of Agribusiness

₹500